Create a WPS in minutes!

WeldTrace supports these standards for writing code-compliant welding procedures: ASME IX (for all of these methods: Groove & Fillet welds, Corrosion Resistant & Hardfacing Overlay welds, tube to tubesheet joints, Lap & Stud welds), AWS D1.1, AWS D1.2, AWS D1.5 (for all of these methods: Maximum Heat Input, Minimum Heat Input, Production Procedure and Fracture Critical welds), AWS D1.6, API 1104 (for all of these methods: Section 5 - with filler metal addition, Section 10 - repairs, Section 12 - mechanized and Appendix B - in-service or hot tapping) and ISO 15614-1 standards for writing code compliant welding procedure specification WPS.

Our templates and workflows are very user friendly and will guide you through the process. They are less intimidating for someone who is not a professional and at the same time if you are a seasoned welding professional you will enjoy the experience.

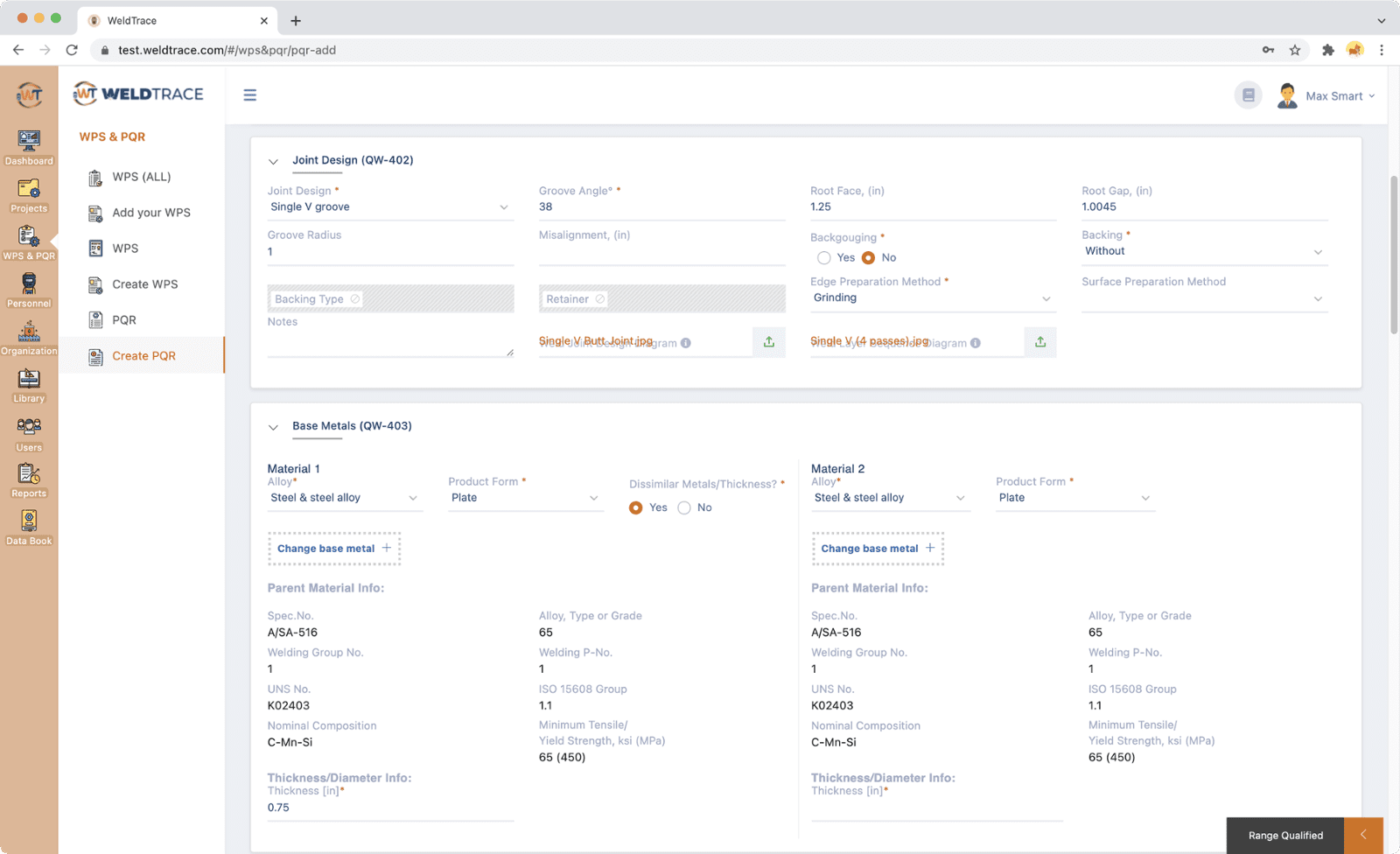

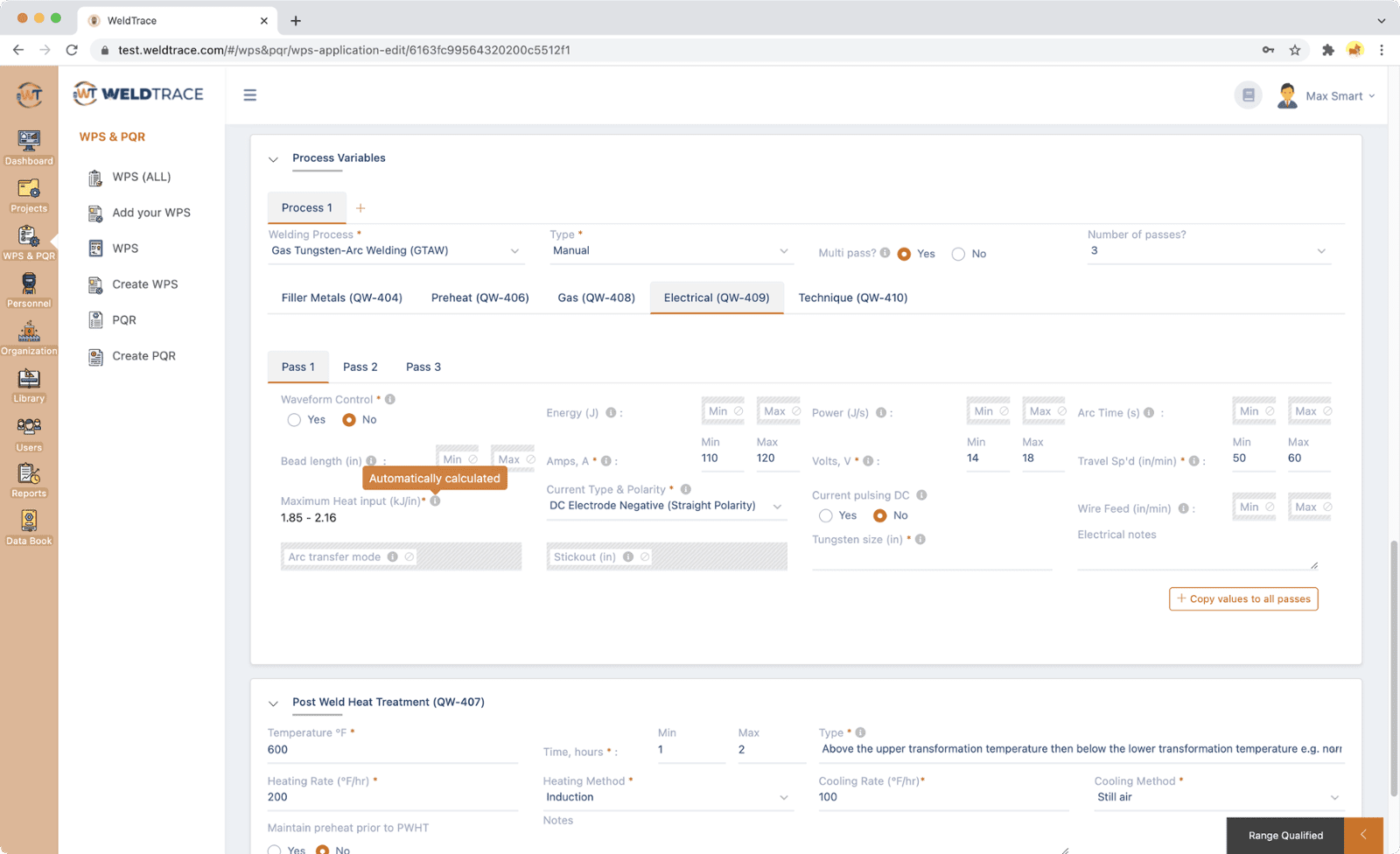

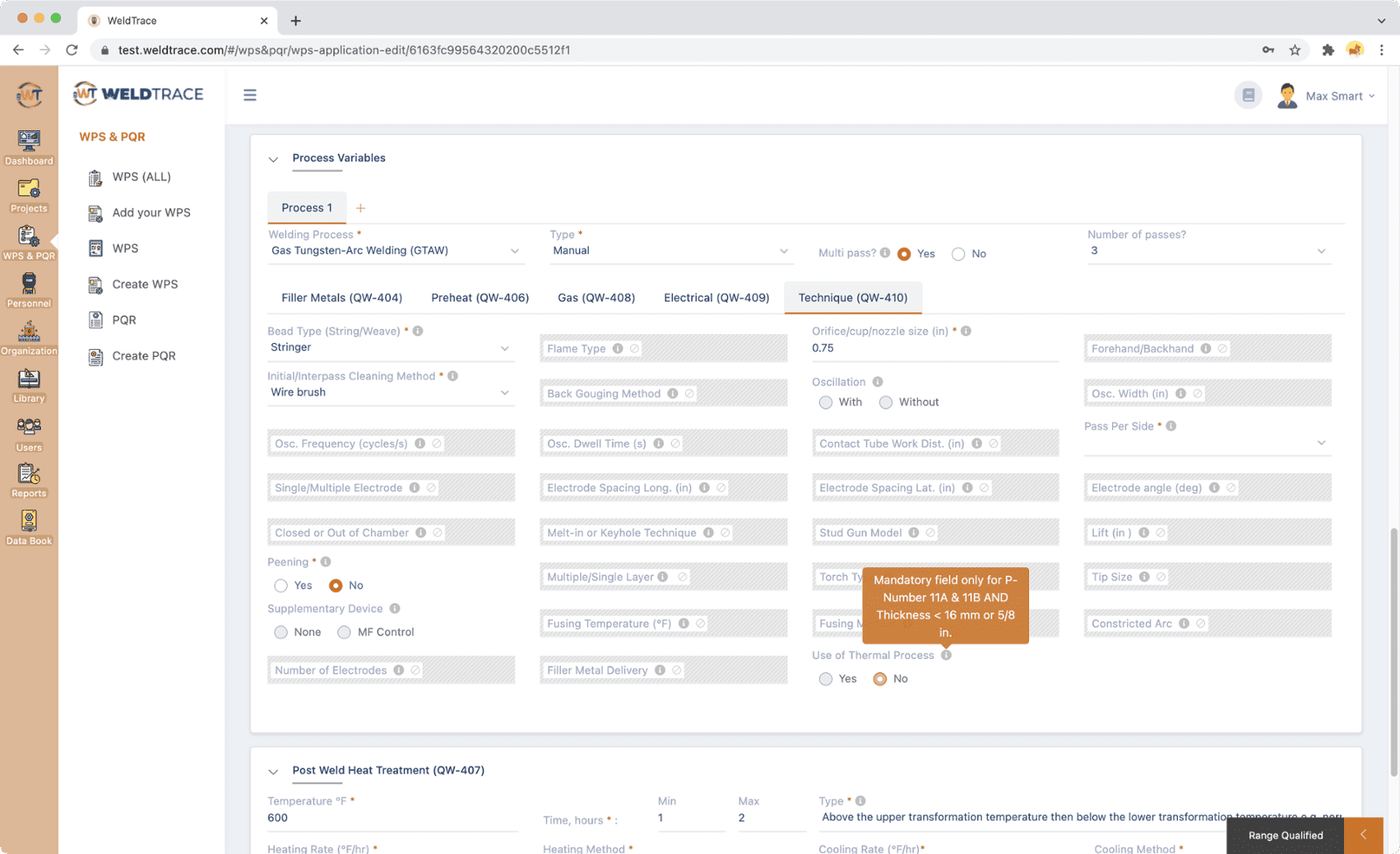

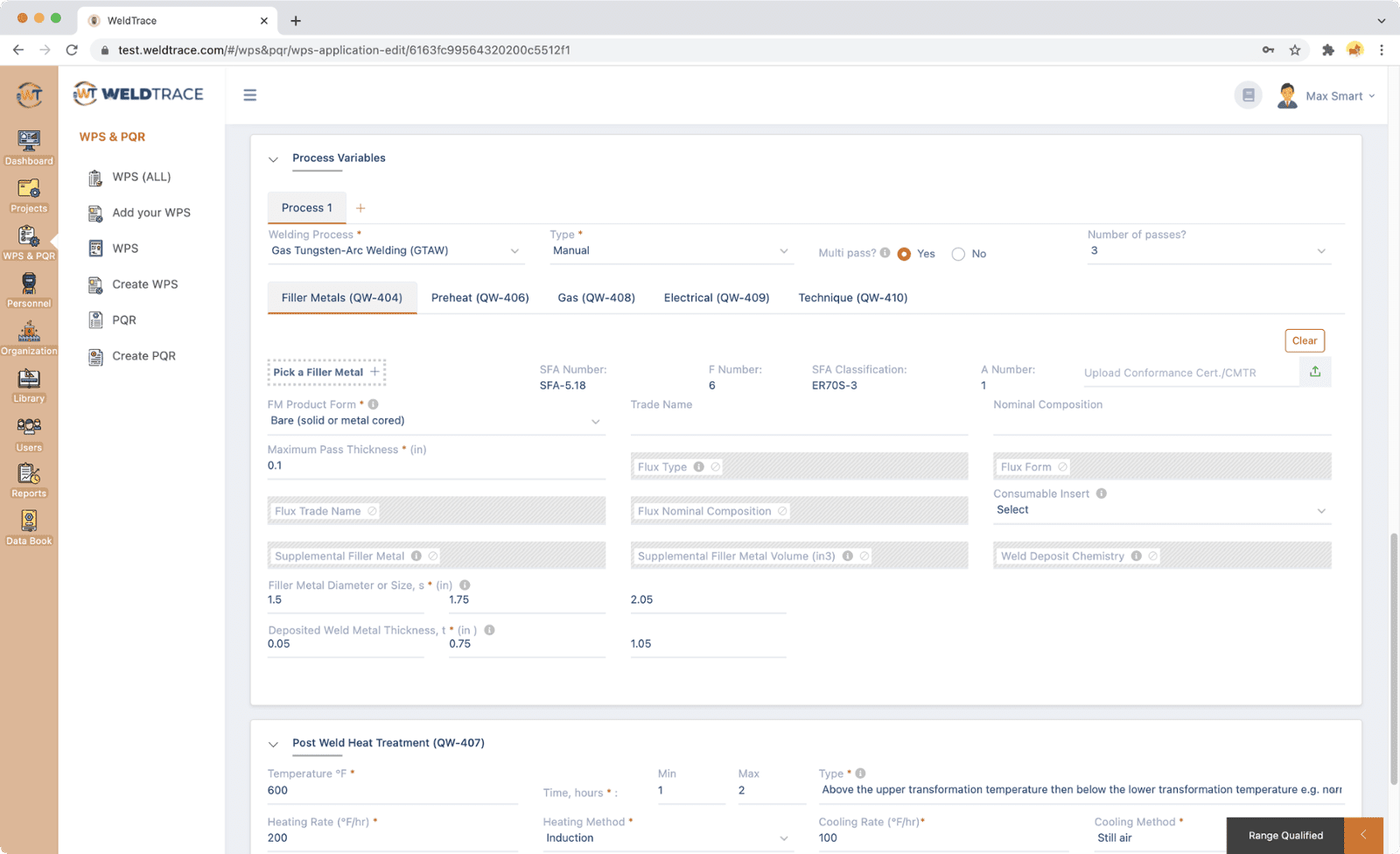

The fields that are not applicable will be hashed out. Essential and supplementary essential variables are highlighted. You can copy values to all passes. Info icons will provide information about a variable.

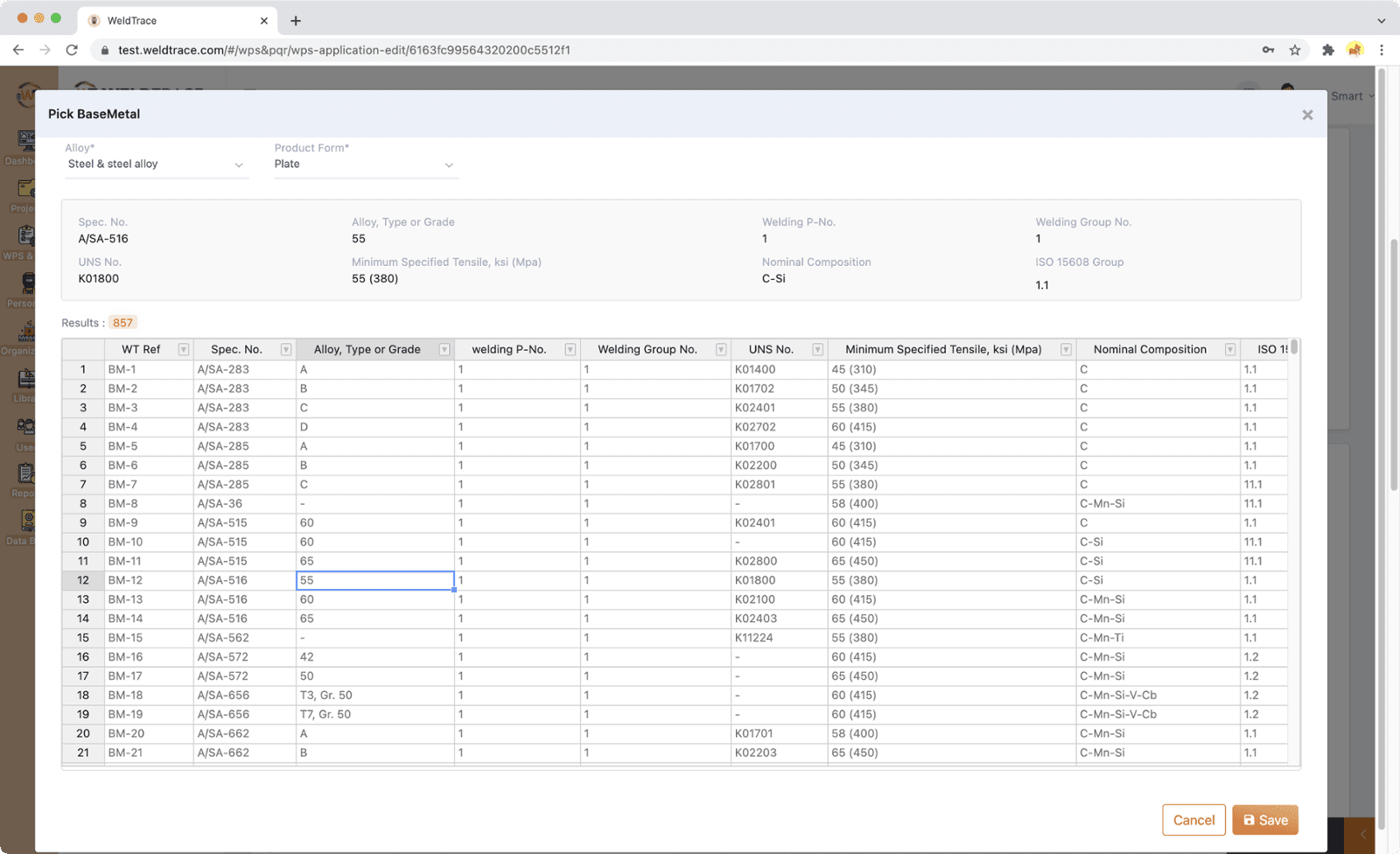

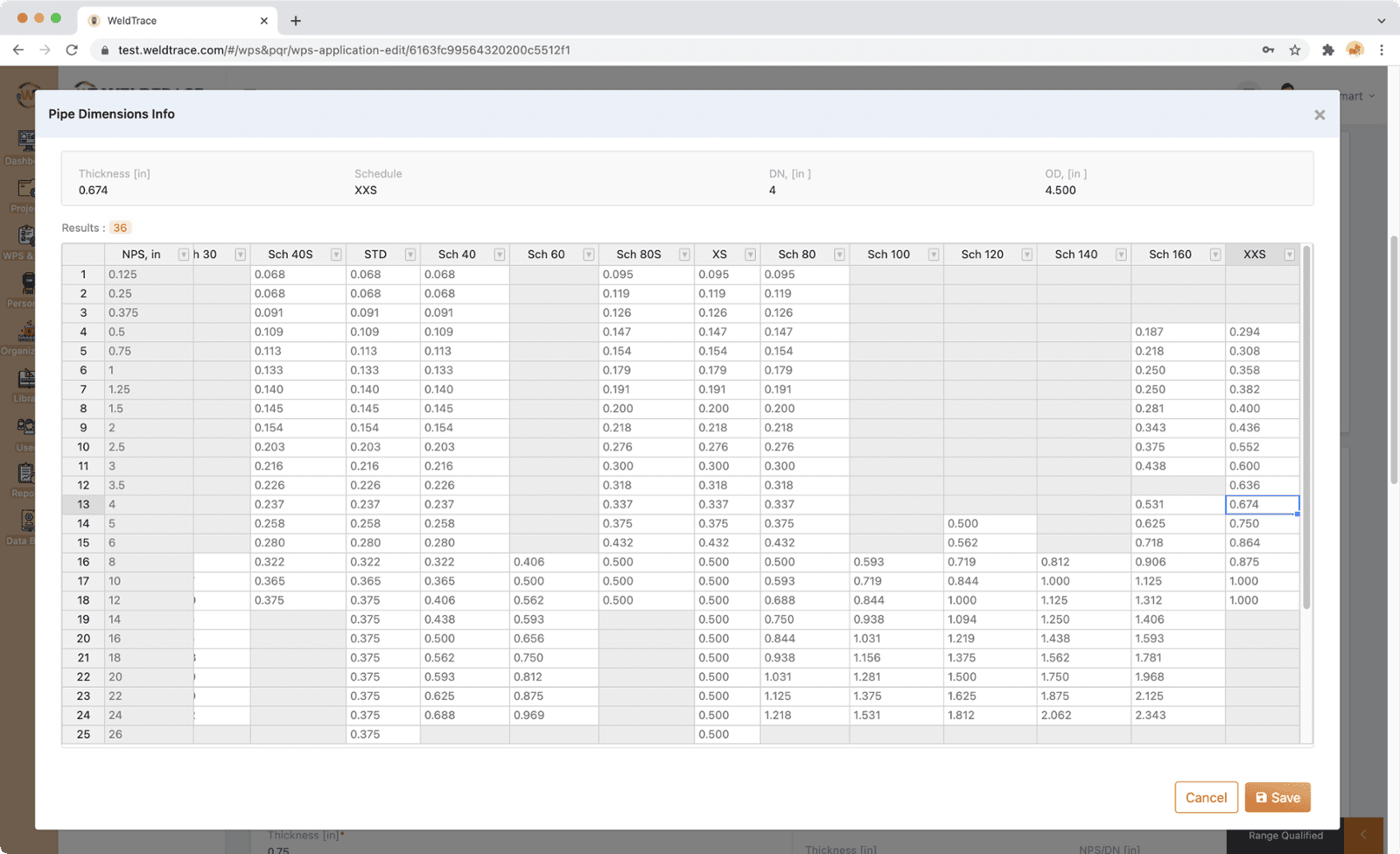

Our library has joint diagrams, layer sequence diagrams, over 5000 AWS & ISO base metals, over 4000 AWS & ISO filler metals, 700 gas mixtures and the pipe dimension chart.

- ASME IX, AWS D1.1, AWS D1.2, AWS D1.5, AWS D1.6, API 1104 and ISO 15614-1 code-compliant templates

- Over 5000 base metals in our database

- Over 4000 filler metals in our database

- Over 700 gas mixtures in our database

- You can add your base & filler metals to our database

- Pipe dimension charts for Metric & English units

- Joint and pass diagrams can be picked

- Essential and supplementary essential variables highlighted

- Fields that are not applicable will be hashed out

Create a preliminary WPS (pWPS)

You need to document a pWPS first and before you can create a PQR and then the WPS.

A preliminary or proposed welding procedure specification (pWPS) serves as a guide for the welder to follow to weld the PQR test coupon. Since you need the variables from the PQR to write the WPS, you need a draft or preliminary WPS first and then qualify it. That is why you need to start with a draft document that can be modified until the procedure qualification results are satisfactory.

The pWPS can also be used as the draft document to get an ok from the client on what you are attempting to write in the final WPS.

There is no cost for creating pWPS in WeldTrace. They are absolutely free.

Watch the full video on how to create a pWPS for ASME IX in our YouTube channel: https://youtu.be/ve8tRmQ8JP0

Create a welding procedure qualification record (PQR/WPQR)

A PQR is the record of the actual welding parameters and test data used in a welding procedure qualification test.

In WeldTrace, you start with a pWPS and create the PQR record from it. The short video below shows how WeldTrace transfers the data from a preliminary WPS to the PQR template automatically. You may quickly edit the data and record the actual welding parameters in the PQR template and enter the test results.

The fields that are not applicable will be hashed out. The fields for essential and supplementary essential variables will be shown as mandatory fields. The fields for non-essential variables will be optional. WeldTrace makes it easy to create a code-compliant welding procedure qualification record and it will only cost you $5 to create a PQR. You cannot find this much simplicity and value in any other welding software.

Watch the full video on how to create a PQR for ASME IX in our YouTube channel: https://youtu.be/LngTGm5ULfI

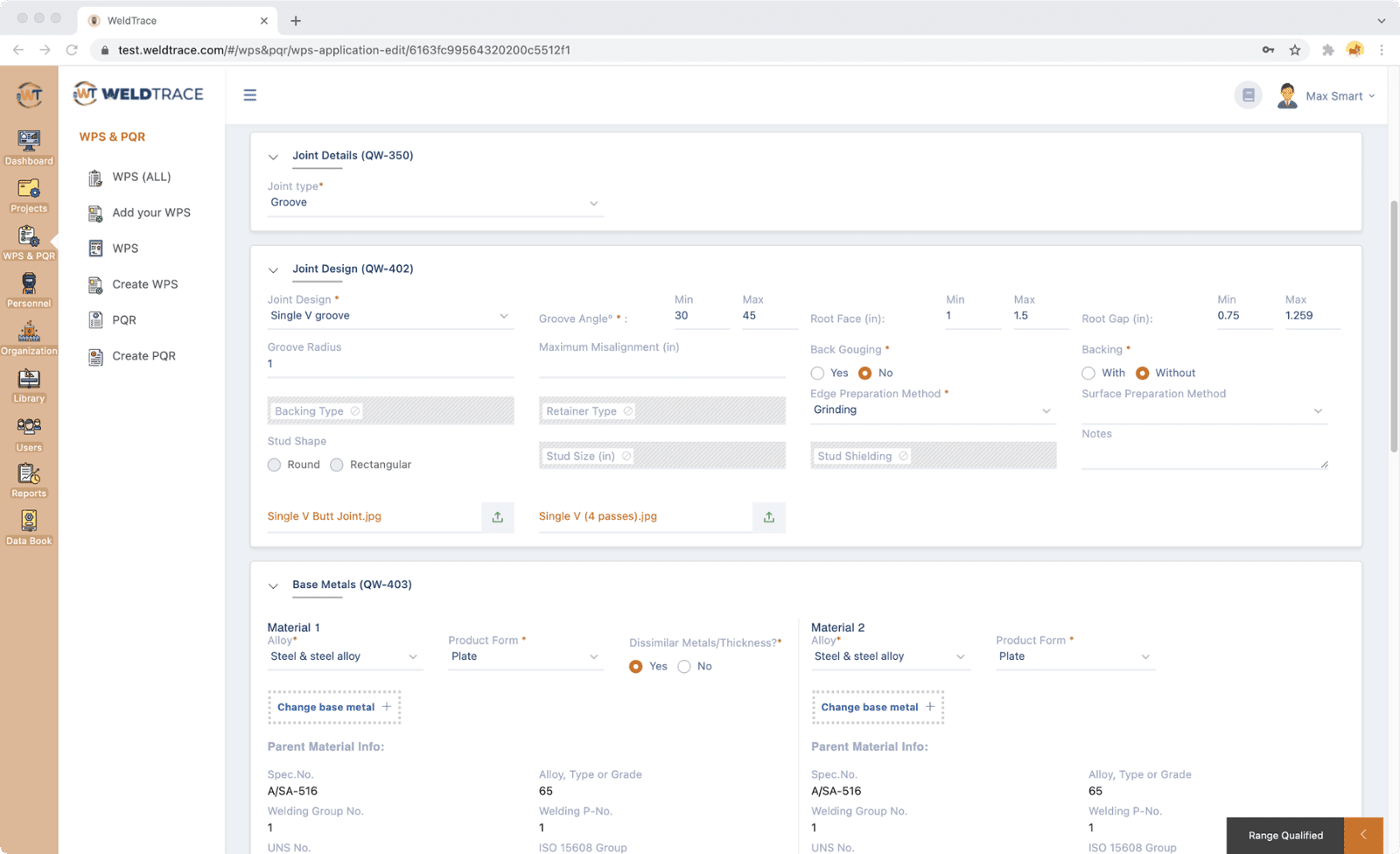

Create a welding procedure specification (WPS)

Once you have a PQR created and approved, you can easily create one or more WPS from it. WeldTrace will automatically create a WPS from the selected PQR, calculate the permitted range qualified values and present them to be edited in the WPS template.

Depending on the code rules, certain fields cannot be edited, the values in certain fields may be changed but they need to be within the PQR's range qualified values, while others may be edited and changed. Code rules for essential, supplementary essential and non-essential variables will be intelligently applied.

The fields that are not relevant will be hashed out, the fields that cannot be edited will appear with a ban symbol, and when you change the values beyond the qualified range you will be shown a warning message. WeldTrace makes it easy to create a code-compliant welding procedure and the best part is it will only cost you $5 to create a WPS. You will not find this much simplicity and value in any other welding software.

Watch the full video on how to create a WPS from a PQR for ASME IX in our YouTube channel: https://youtu.be/QQC43klNraE

Guided through the process with help available in every step

WeldTrace leaves little for guesswork as the forms in the software to create the preliminary welding procedure specification (pWPS), WPS and the procedure qualification record (PQR) are dynamic and driven by code rules. Depending on the base metal, product form, joint type, process and so on, the fields that are shown are based on the requirements in the standards. You will find tooltip help messages near each field label, knowledge base snippets within the page, and explainer videos, so you are always in command.

- Code rules determine the workflow

- Fields are enabled or disabled based on code rules

- Info help messages near the field

- Range qualified values displayed as you build the form

Create pWPS, pWPS to PQR, PQR to WPS with data validation

WeldTrace offers automated workflows for creation of pWPS, pWPS to PQR, a single PQR to WPS, multiple PQRs to WPS and WPS to welder qualification. When a WPS is created from a single PQR or multiple PQRs, you will be able to remove a process or move the processes around, like root to cap, if the code permits the operation. All of them support up to 3 processes in each document. You will be able to edit and change values within the range qualified values depending on if it is an essential variable, supplementary essential variable or a non-essential variable.

WeldTrace is the welding procedure software for ASME IX, API 1104, AWS D1.1, AWS D1.2, AWS D1.5, AWS D1.6 and ISO 15614-1.

Check the knowledge base articles in our help center: Welding Procedures & PQR.

- Create a draft or preliminary WPS

- Create a PQR from the pWPS

- Create a WPS from a PQR

- You will be allowed to make changes only within the range

- Powerful search to show only the matching WPS or PQRs

- Code rules applied automatically in each stage