Total welding management software

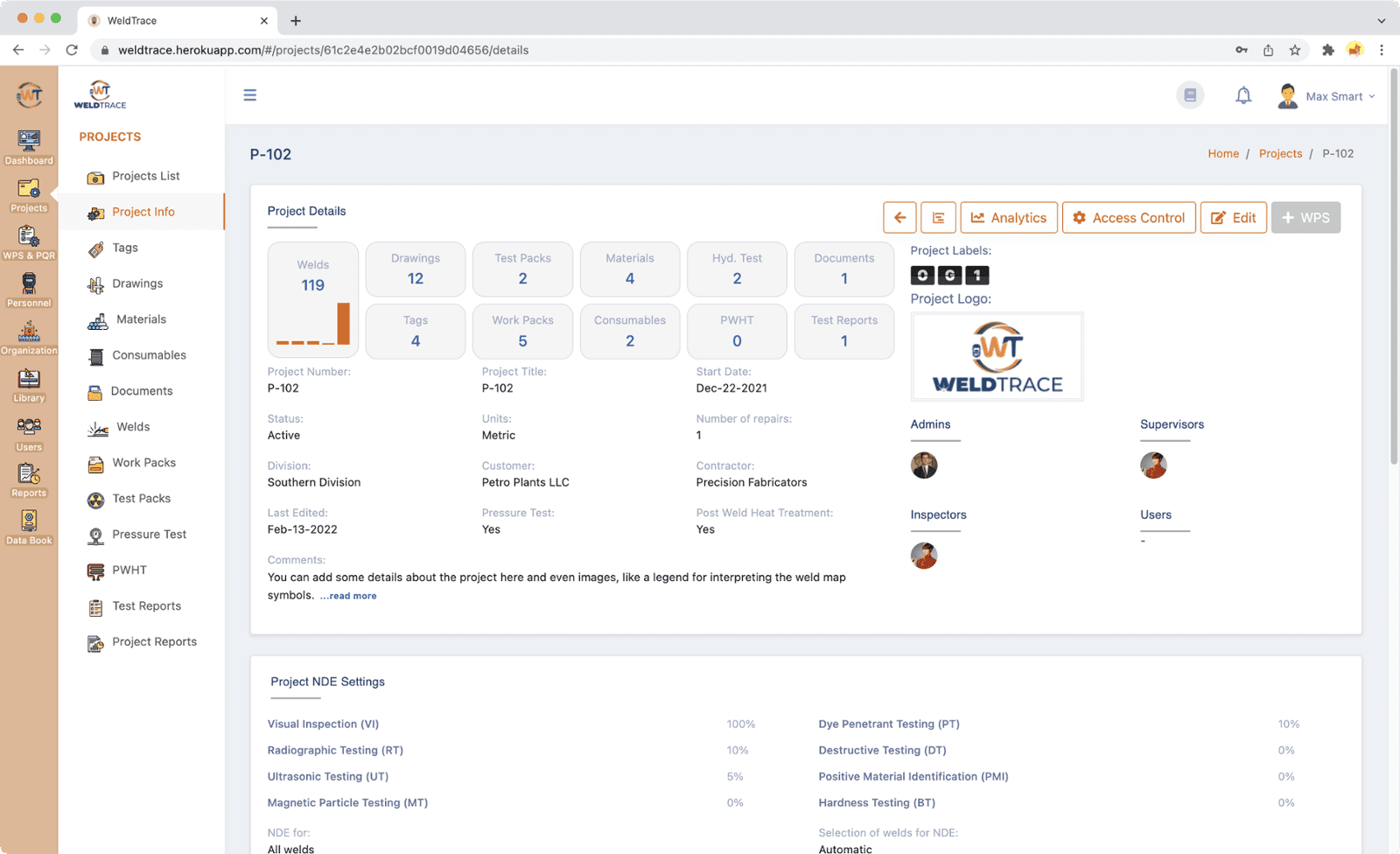

WeldTrace is a total welding management software for fabrication projects of all complexities. Be it a small job or a very large project, WeldTrace can be configured to handle the project requirements or client specifications. WeldTrace's project module has been built to handle all codes with its own workflow which is very easy to learn. A single person can manage a job or hundreds of users can collaborate in a large project with each user's role allowing them to handle specific tasks. WeldTrace is an ERP software for welding.

Experience the power and simplicity of WeldTrace - the end to end welding management software.

Watch this video in our YouTube channel to find out more: Managing Welding Projects

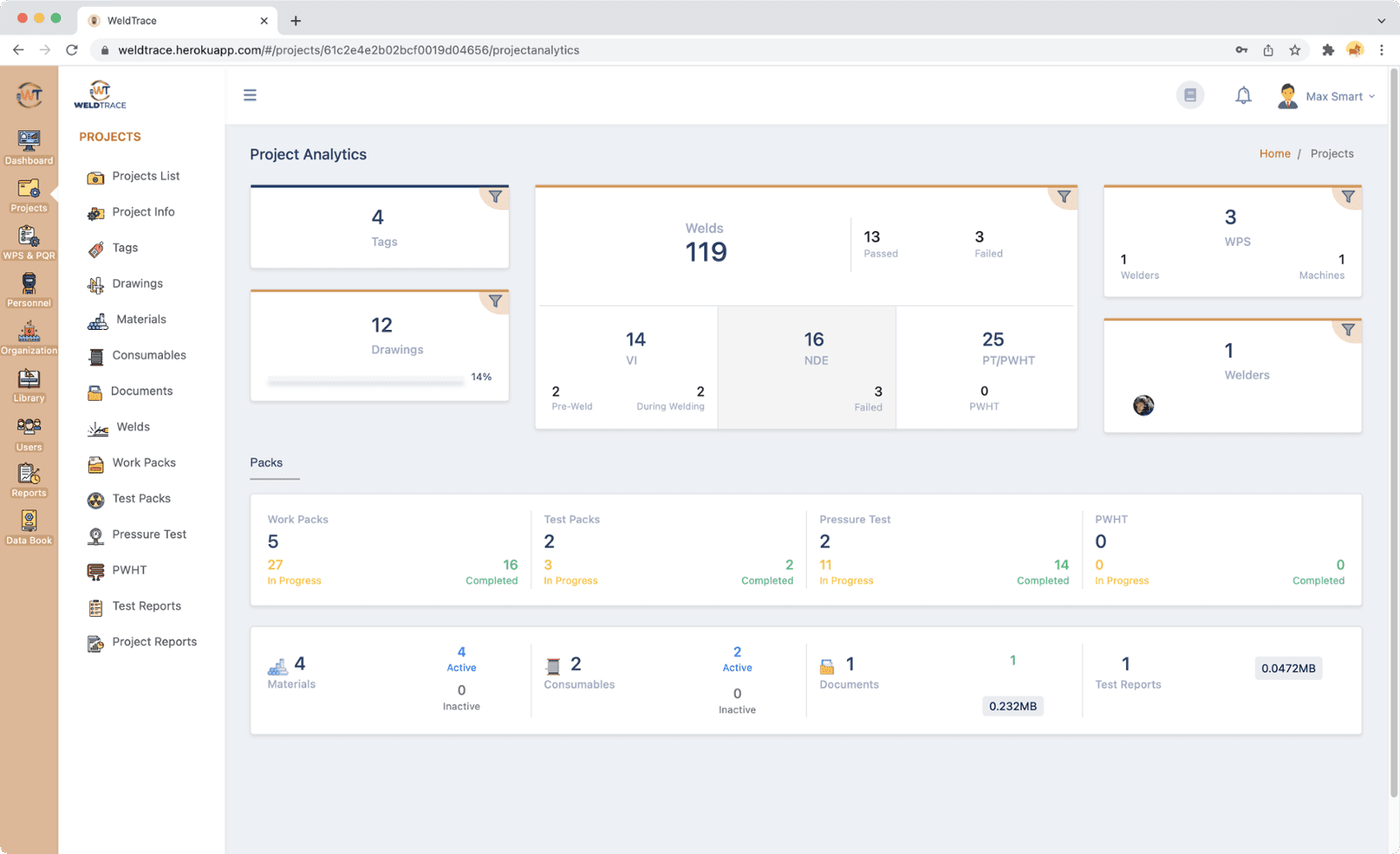

- Manage a few welds to tens of thousands with ease

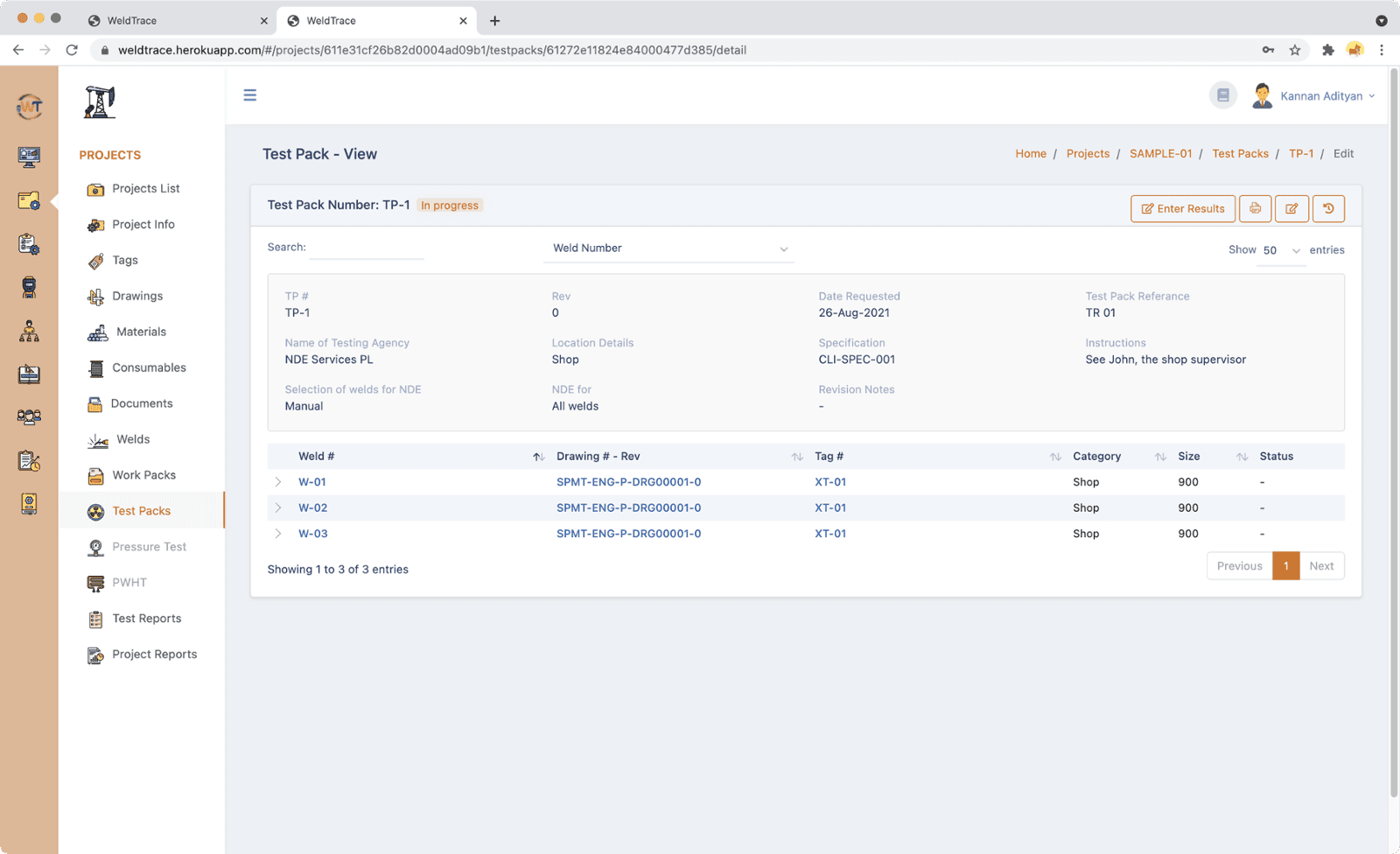

- Visual inspection and NDE modules

- Manage all the drawings with version control

- Repositories for materials and consumables

- Full traceability for each weld

- Weld mapping and dimension mark-up

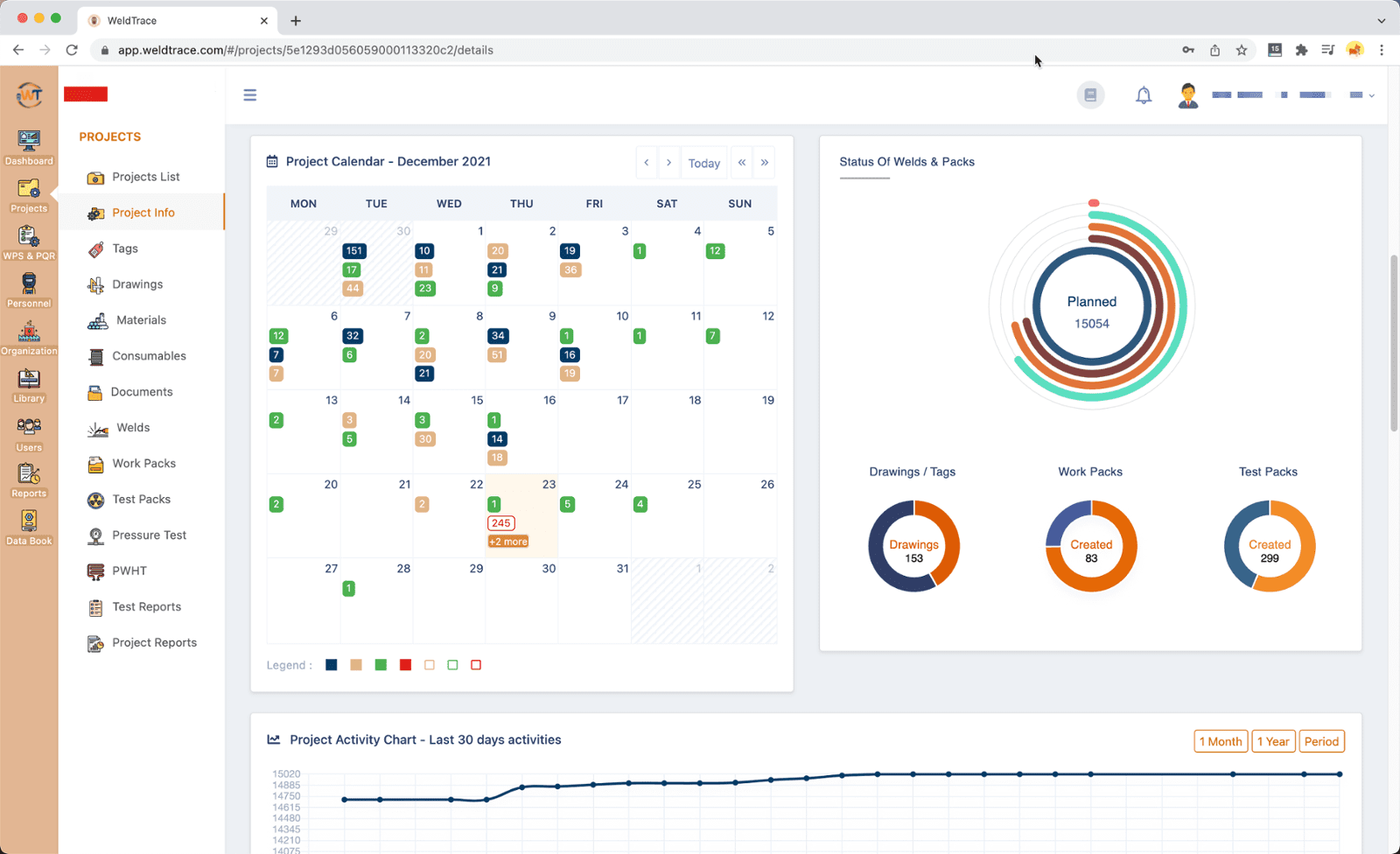

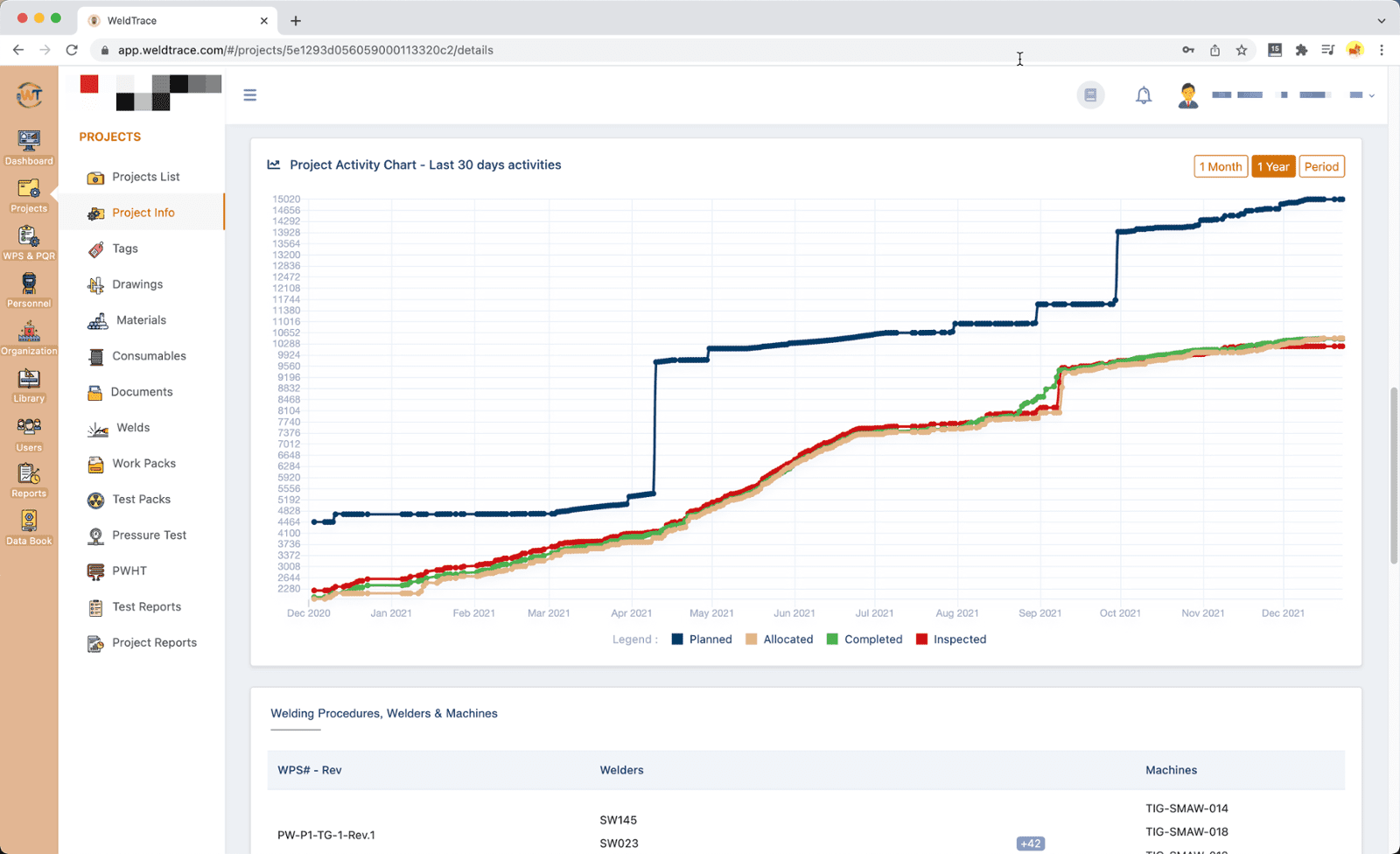

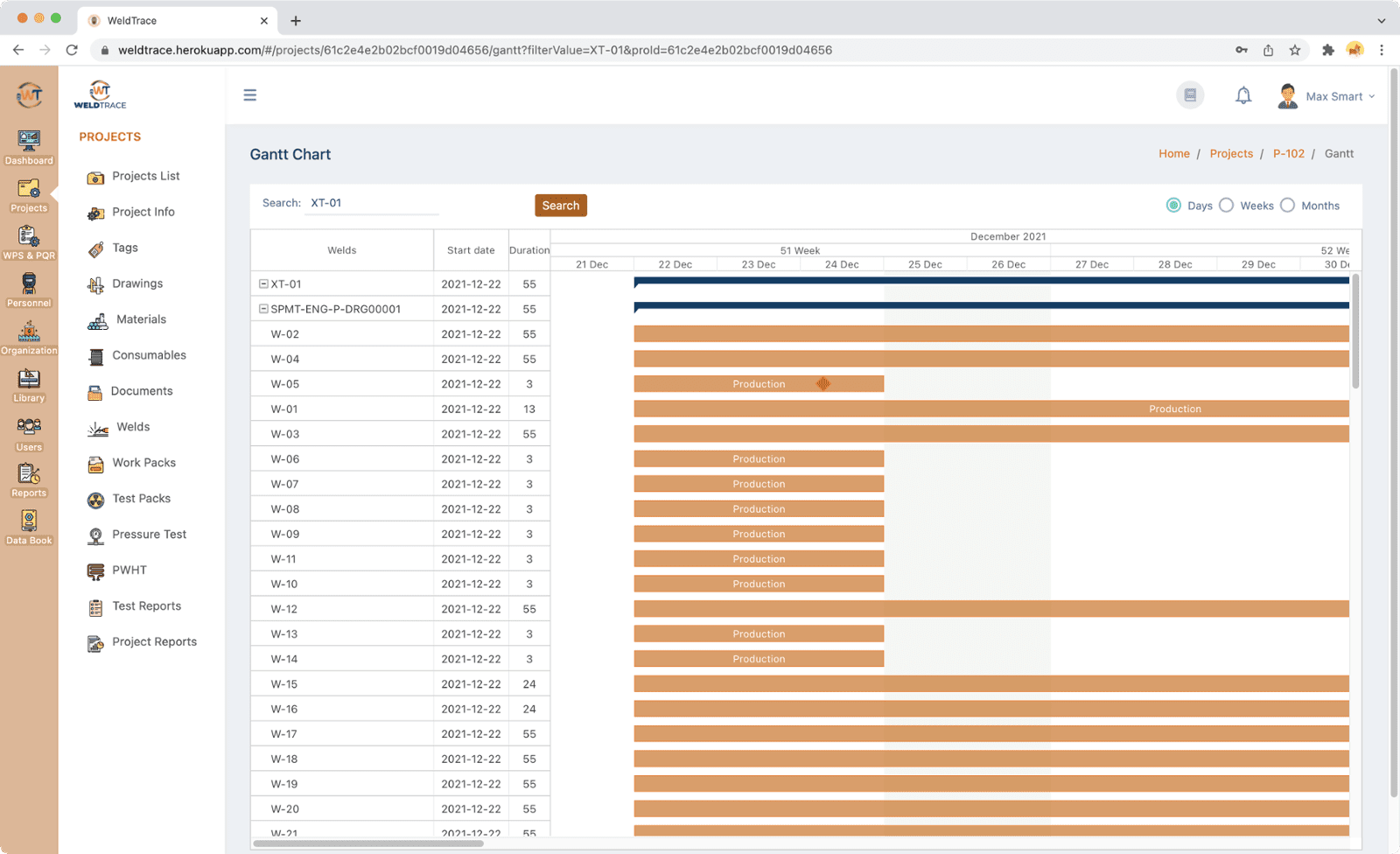

- Project calendar and Gantt chart views

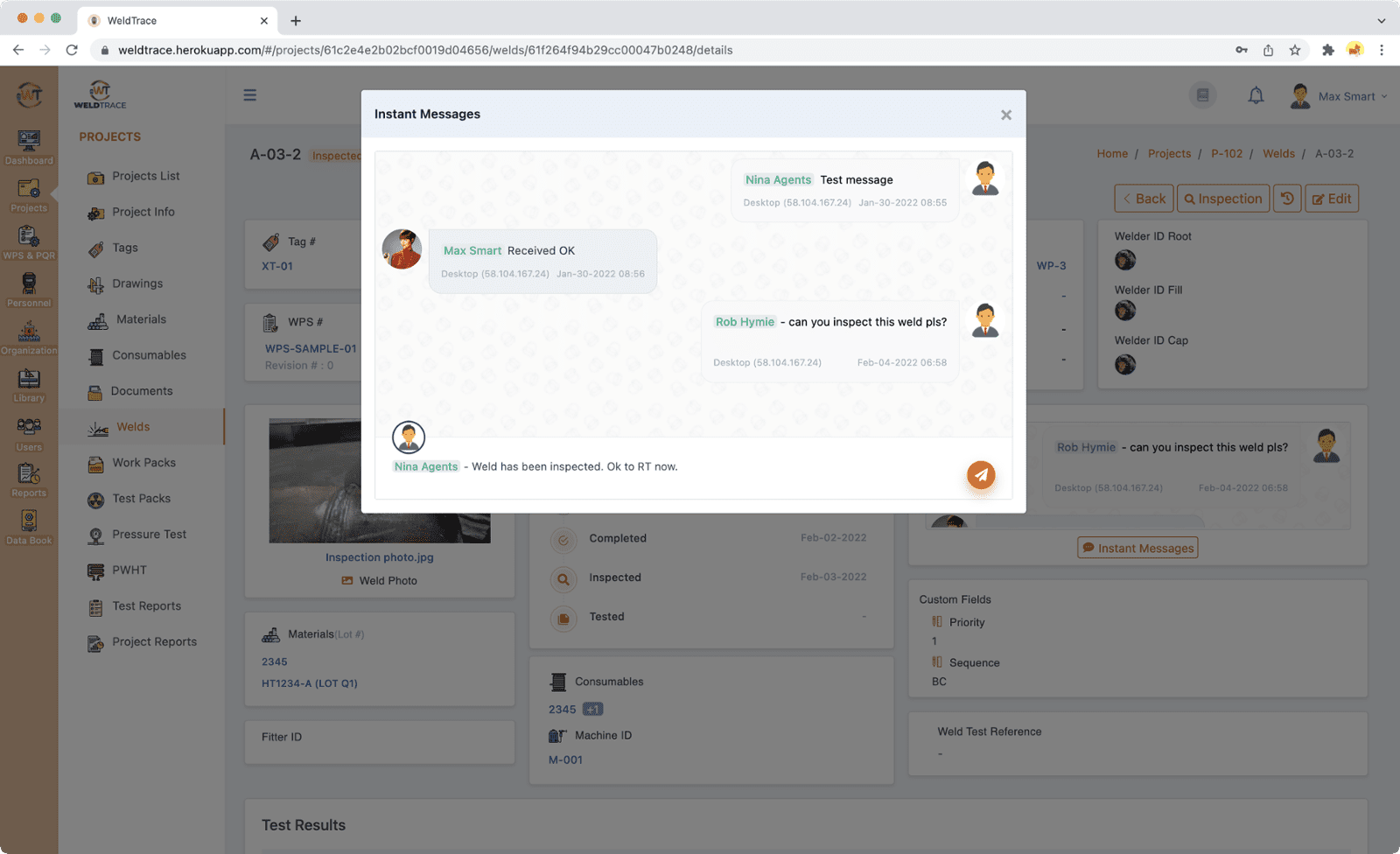

- Instant messaging between users, notifications and alerts

Weld Mapping

WeldTrace offers a weld mapping tool to mark-up welds on drawings. It is a pictorial mark-up tool that will allow you to select a shape, colour and simply draw. Once a weld number is entered, subsequent weld numbers will be automatically entered in the sequence. You can also set attributes such as size and weld type. Welds can be automatically created for the welds mapped on the drawing. You may also leave notes on the drawing that won't be created as welds. In the view weld map mode, users can navigate to the welds from the weld map. All the traceability data for every weld like heat number, WPS, welders and so on are taken care of by WeldTrace automatically. WeldTrace also offers a module where dimensions can be recorded and you can produce as-built drawings.

Visit this page in our help center for more information: Weld Mapping

Watch this short video in our YouTube channel: Pictorial weld mapping

- Weld mapping tool

- Weld numbers marked up in sequence automatically

- Create welds automatically

- Pick attributes of welds like size, joint or weld type

- View weld map and navigate to weld

- Produce high quality weld map prints

- Edit and move weld map annotations

- Transfer weld map annotations when drawings are revised

Repositories for project data

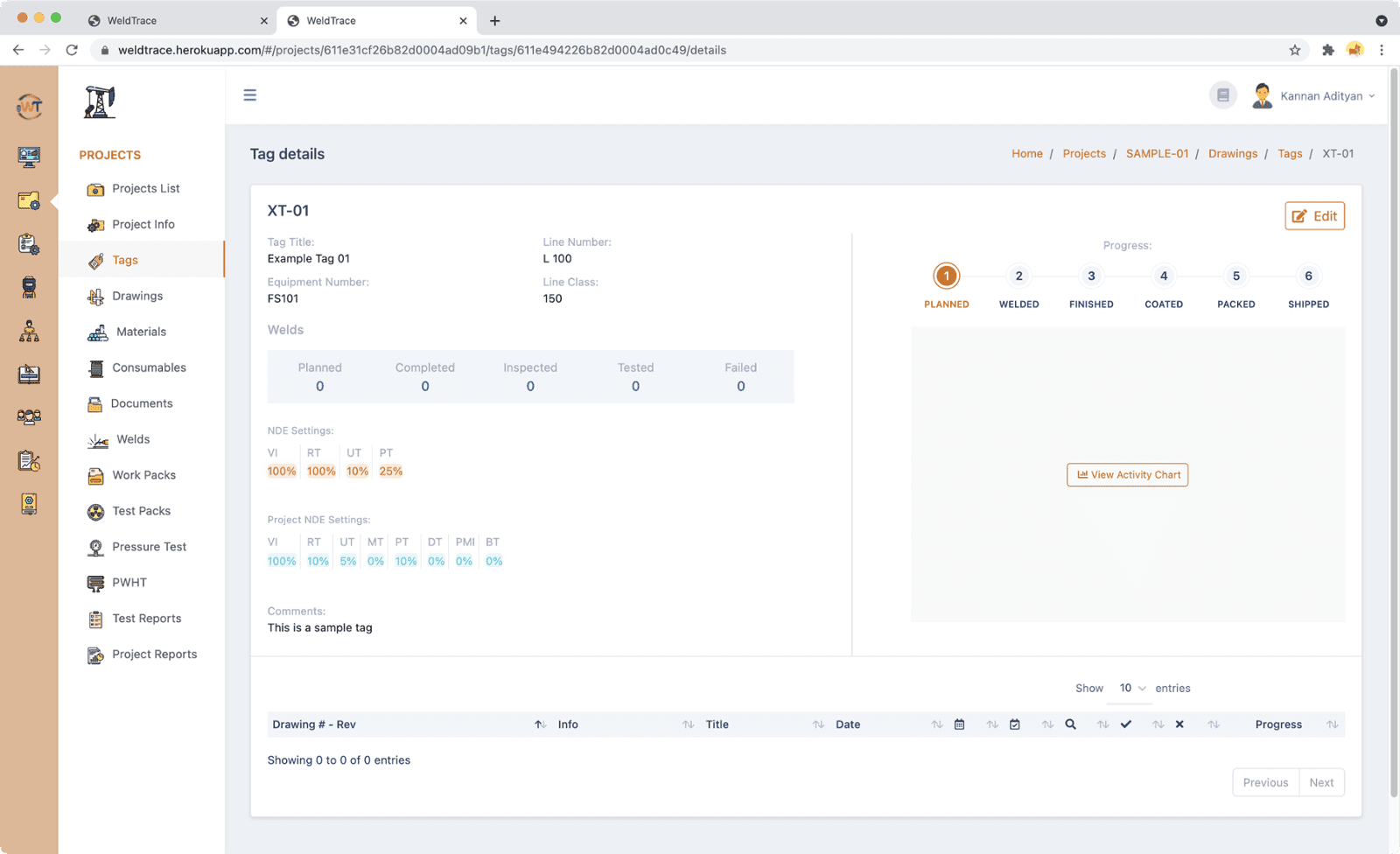

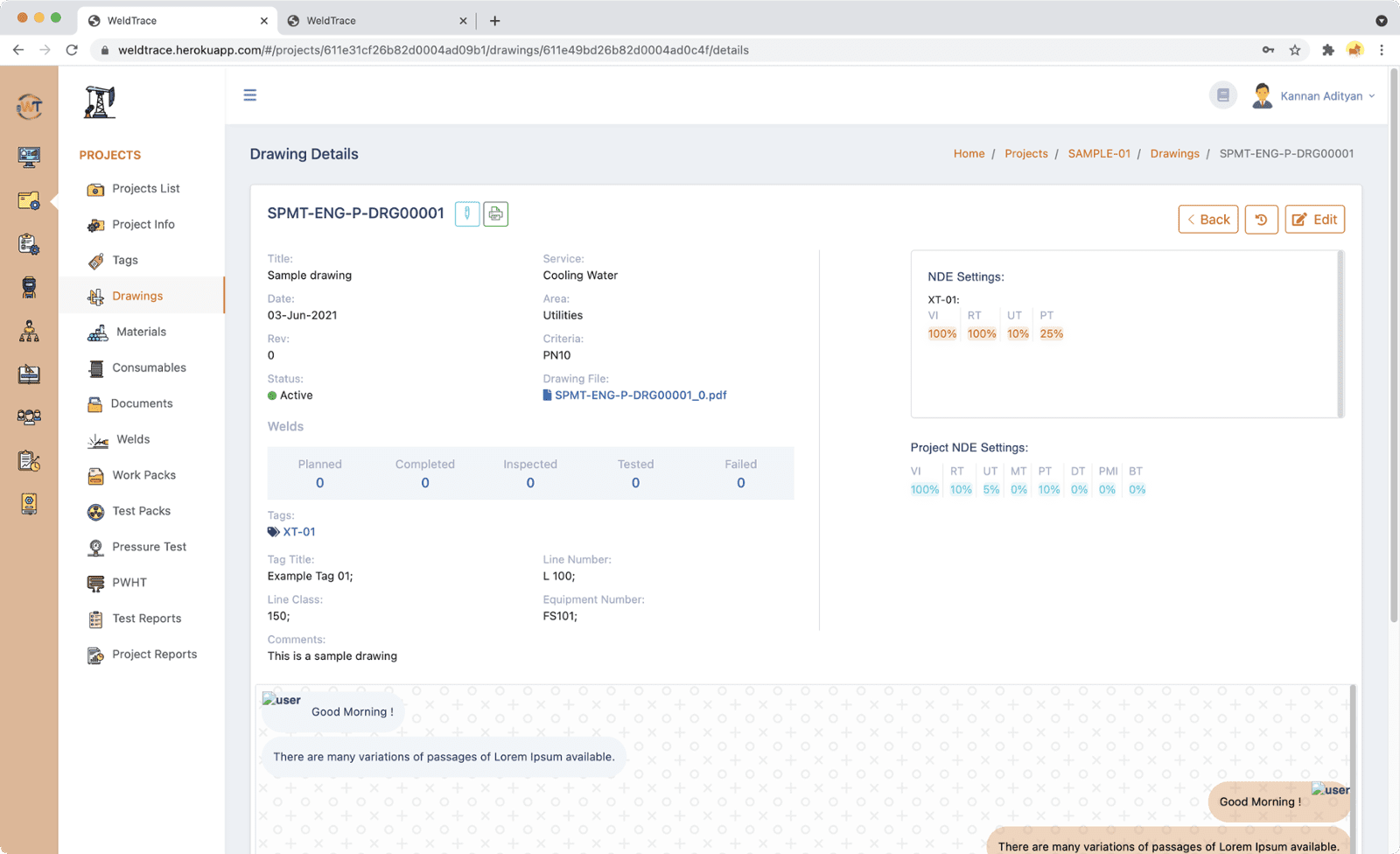

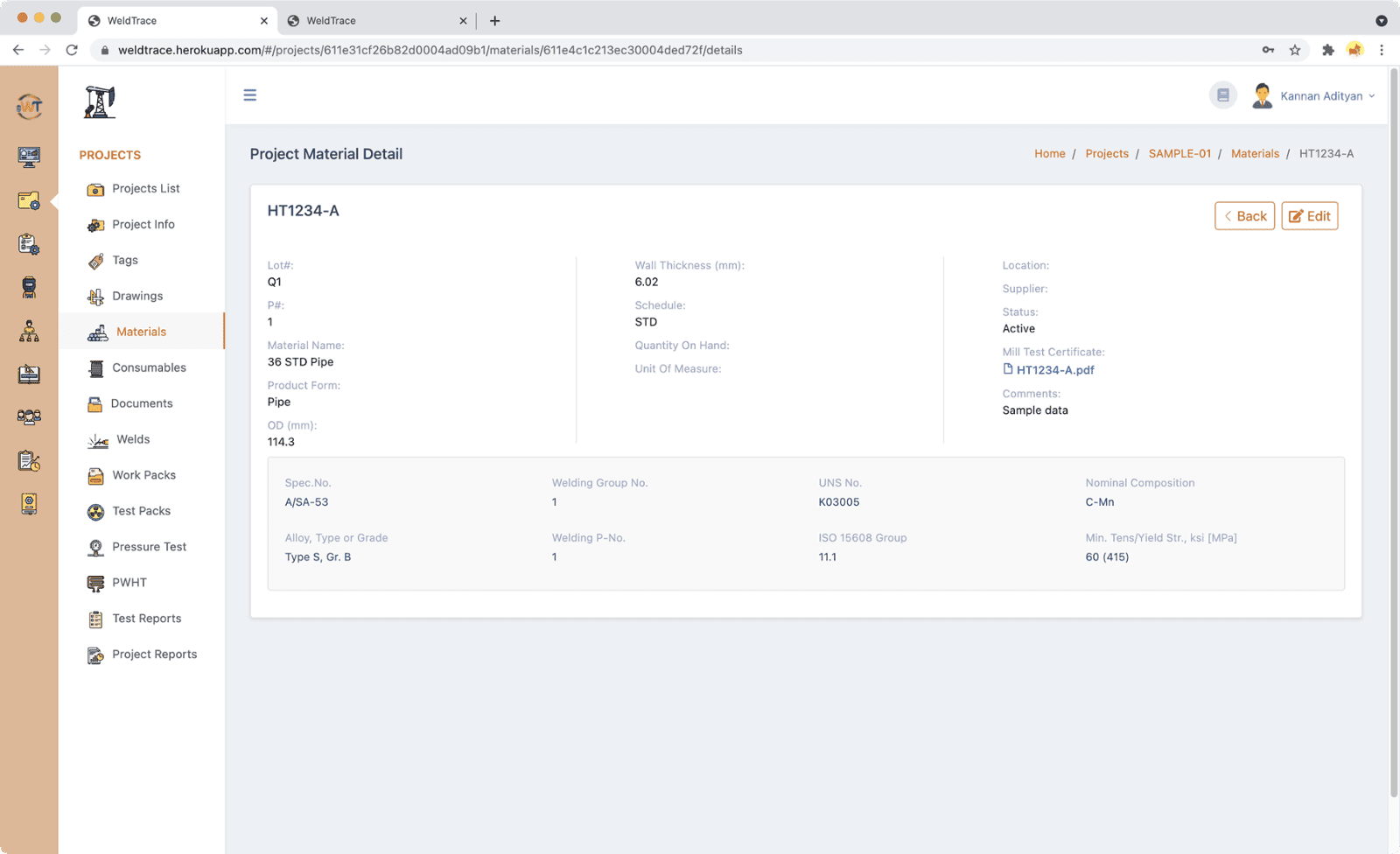

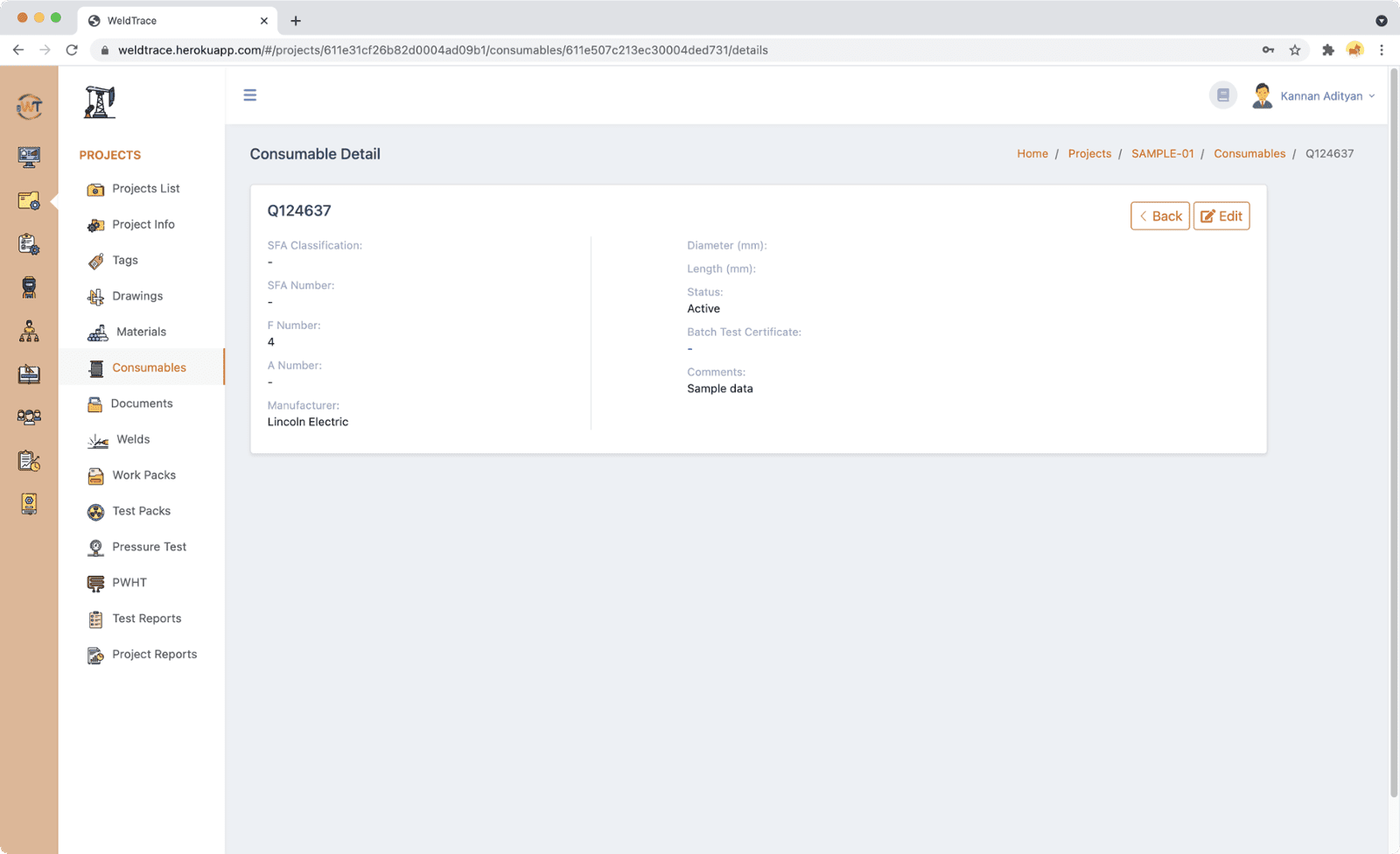

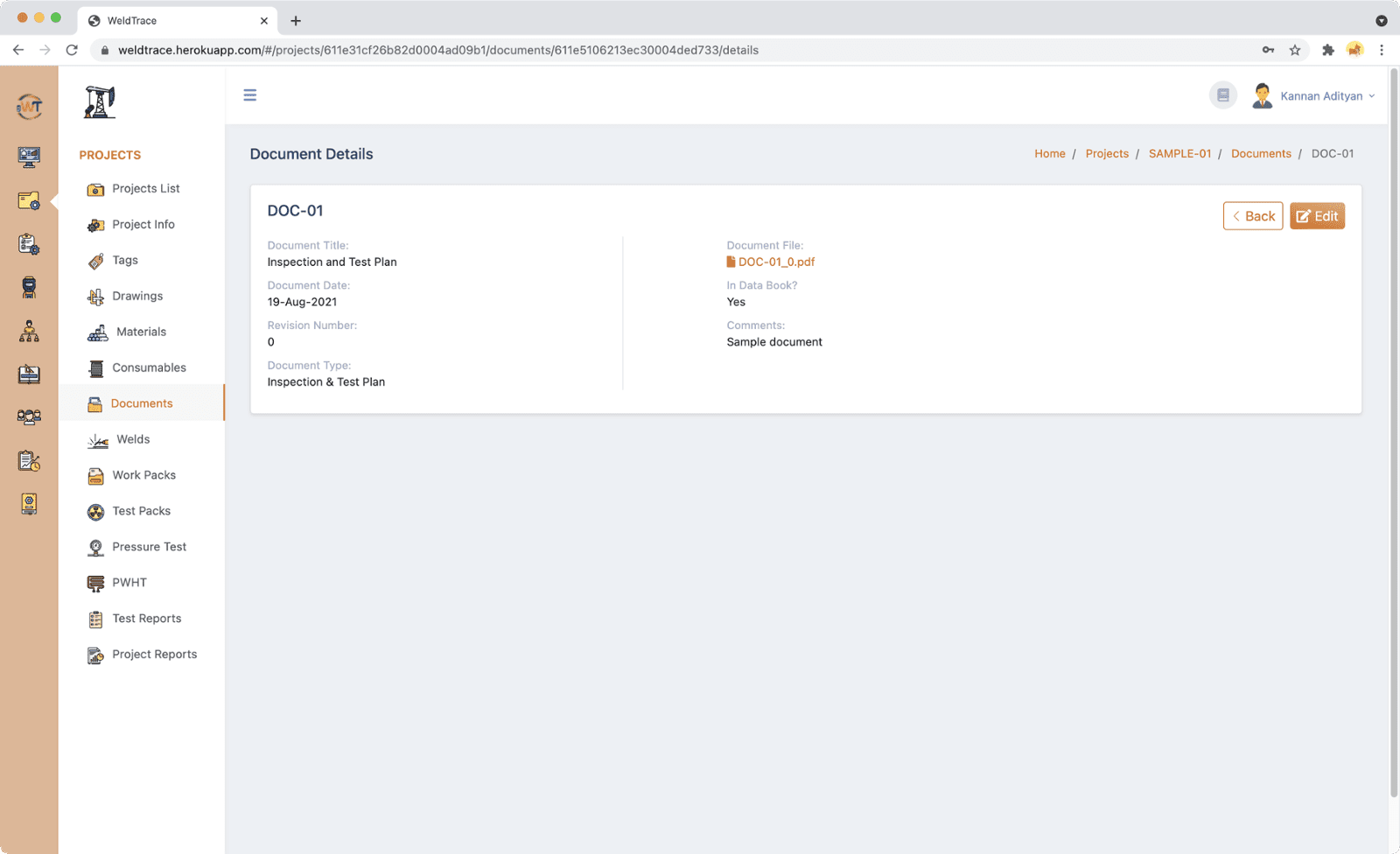

WeldTrace provides separate repositories or areas in each project for tags, drawings, materials, consumables, documents, and test reports. There are common areas or modules for WPS & PQR, welders, fitters and machines where data can be stored and managed centrally that can be used across all the projects.

It is also easy to add data to WeldTrace. You can also bring your own data and files with our easy to use wizards. WeldTrace provides a form style interface for adding one data at a time, an Excel spreadsheet style interface to add many lines of data and bring in a large set of data by uploading a file. You can also bulk upload file attachments like drawings that will get matched with the appropriate record. Repositories are access controlled with read, add, edit or no access based on the user's role.

- Tags to manage fabricated items with multiple drawings

- Drawings with version control

- Materials repository manage heat numbers & MTCs

- Project documents with version control

- Test reports for NDE and visual inspection

- Use welding procedures from the central WPS module

- Welders are stored and managed in a central repository

Welding workflow management made easy!

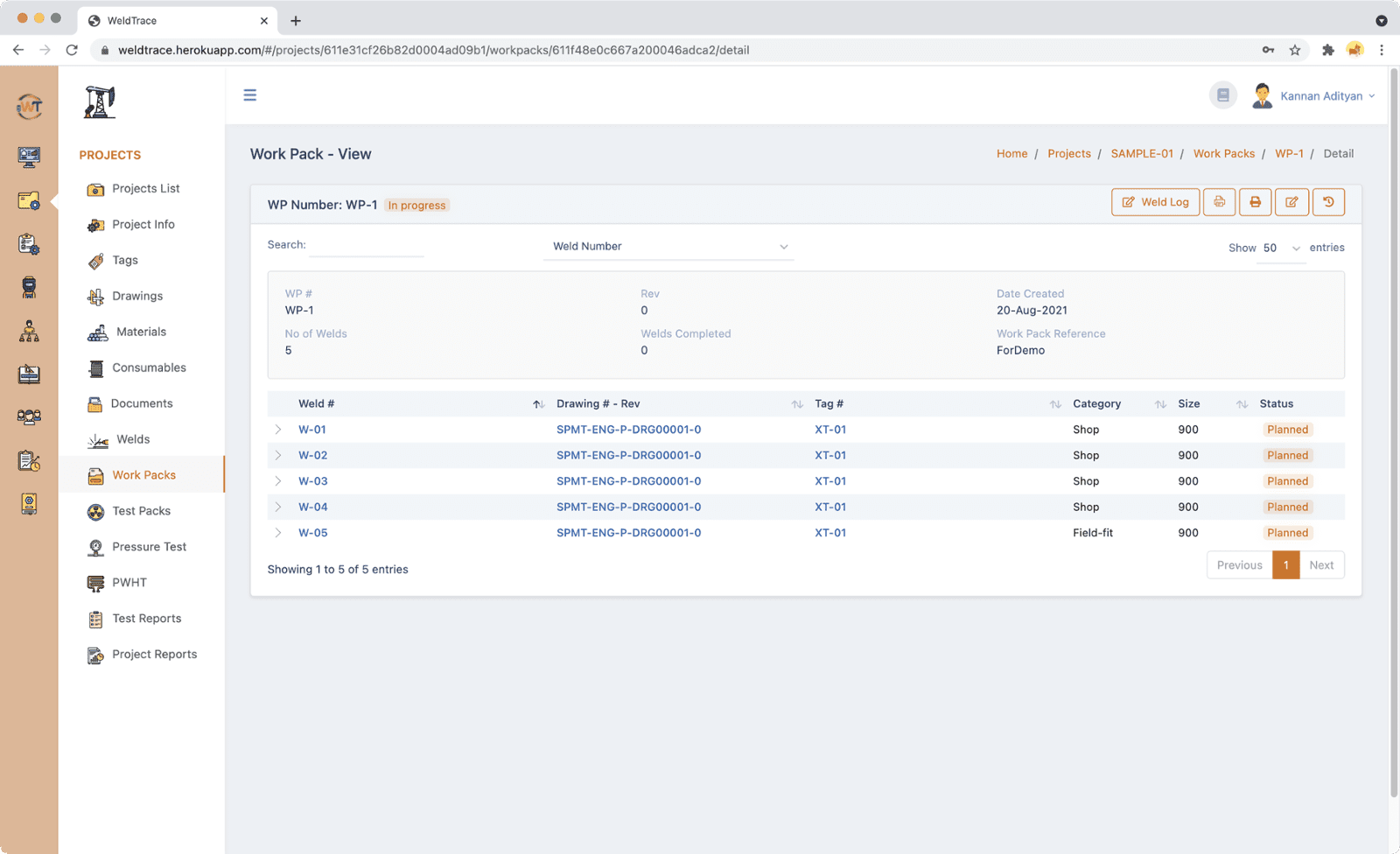

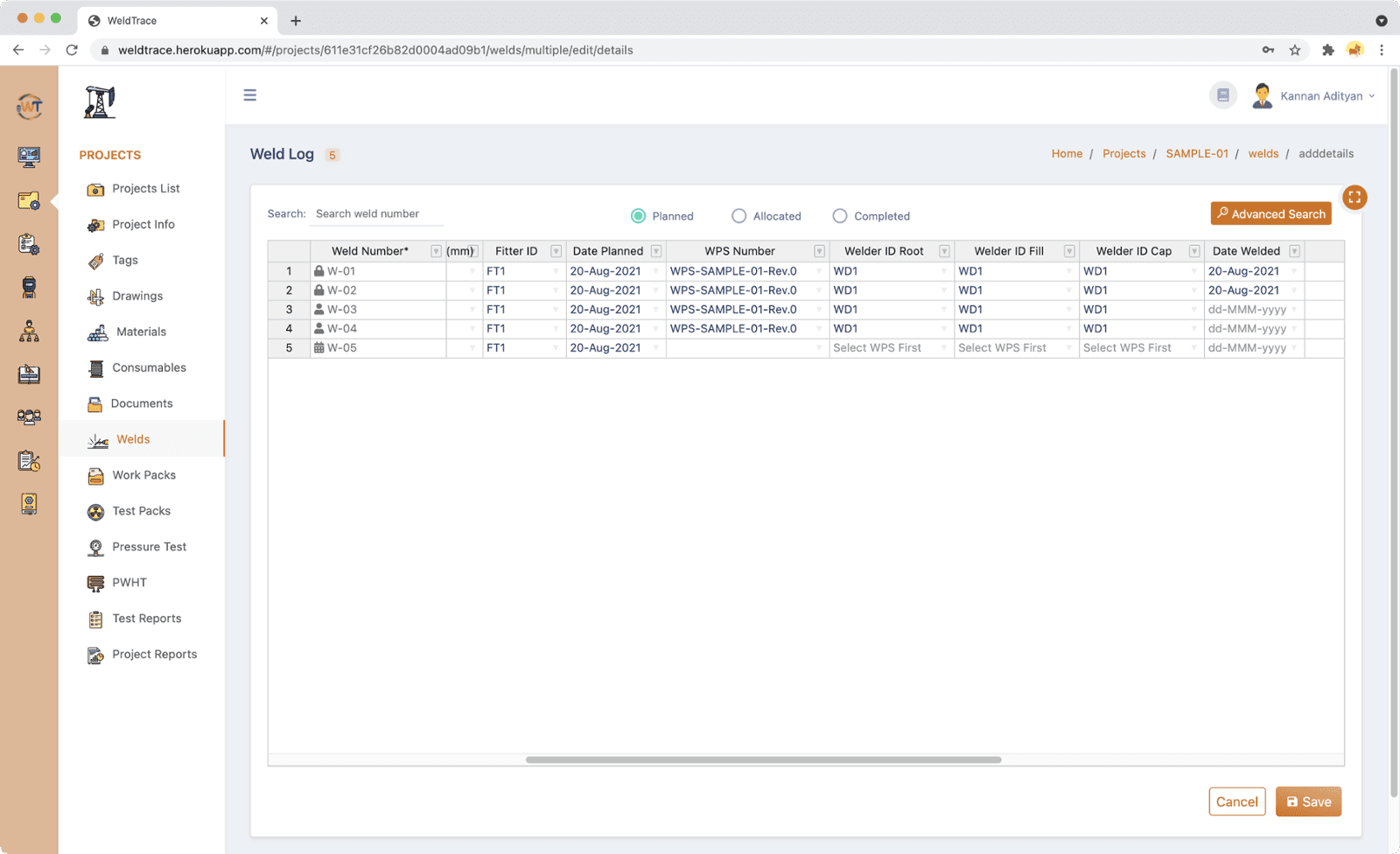

WeldTrace has a built-in work flow for managing a weld's lifecycle from planning to allocating WPS and welders, stage-wise inspection, through to completion and testing. WeldTrace will automatically create repair welds based on the project settings.

Welding supervisors can manage the allocation of welders to weld joints, material traceability, marking welds as complete and then to arrange inspection and NDE.

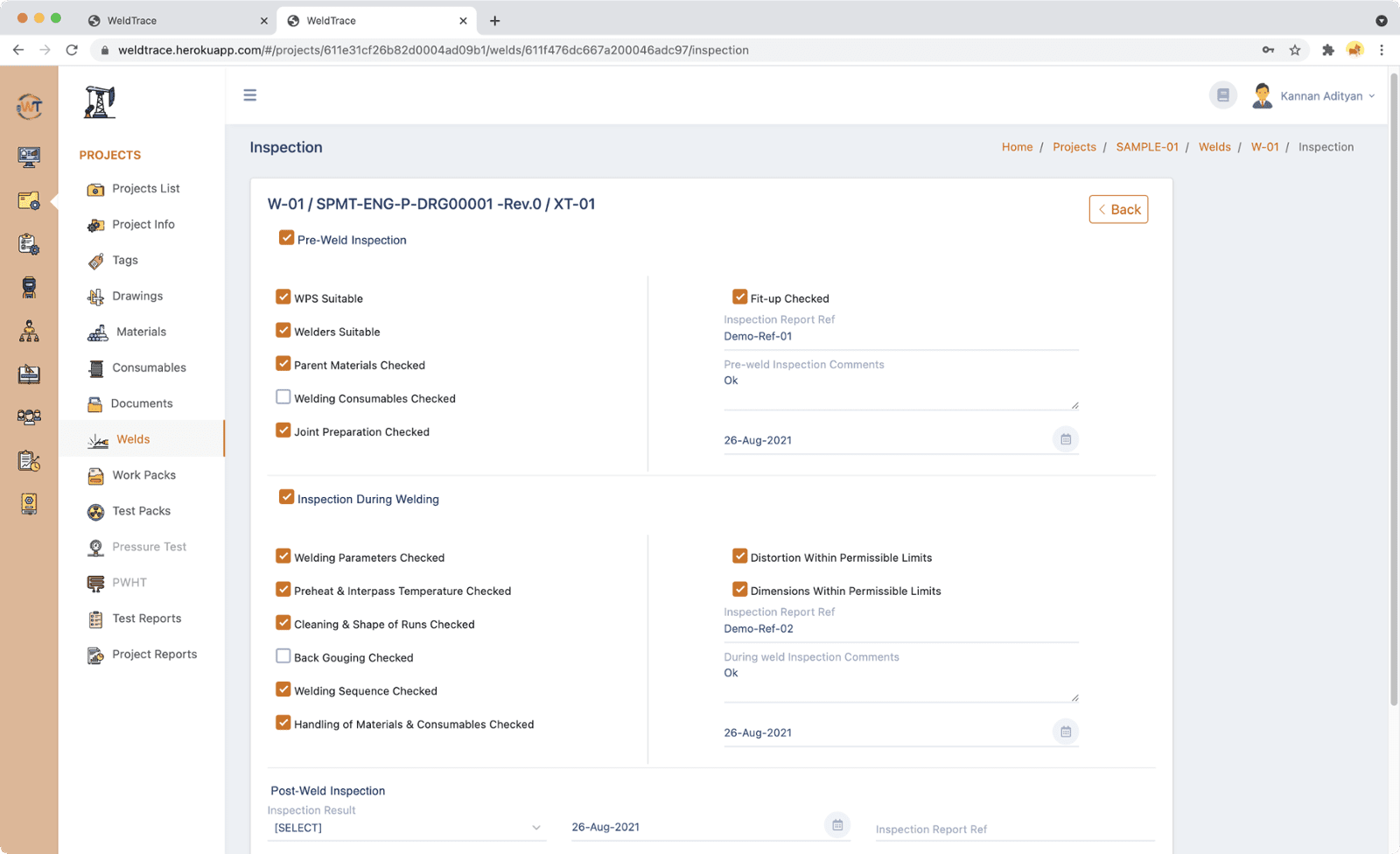

Welding inspectors can perform stage-wise inspection of welds from fit-up, checking and recording during welding if the welding parameters were in accordance with the WPS and post weld inspection.

Generate QR code labels for welds and give login access for users. Welders, welding supervisors and inspectors can use the mobile app to scan QR codes and access weld data.

You can use all of the features or some of them. WeldTrace offers the flexibility to manage your welding projects that would suit your company's culture. Calendar, Gantt chart, dashboard, alerts, progress bars and status counts will make managing fabrication projects that much easier. Users can exchange instant messages that will help them complete welds or organize inspection and testing.

WeldTrace is a complete platform for managing all the welding activities.

- Built-in workflow for weld lifecycle - planning to testing

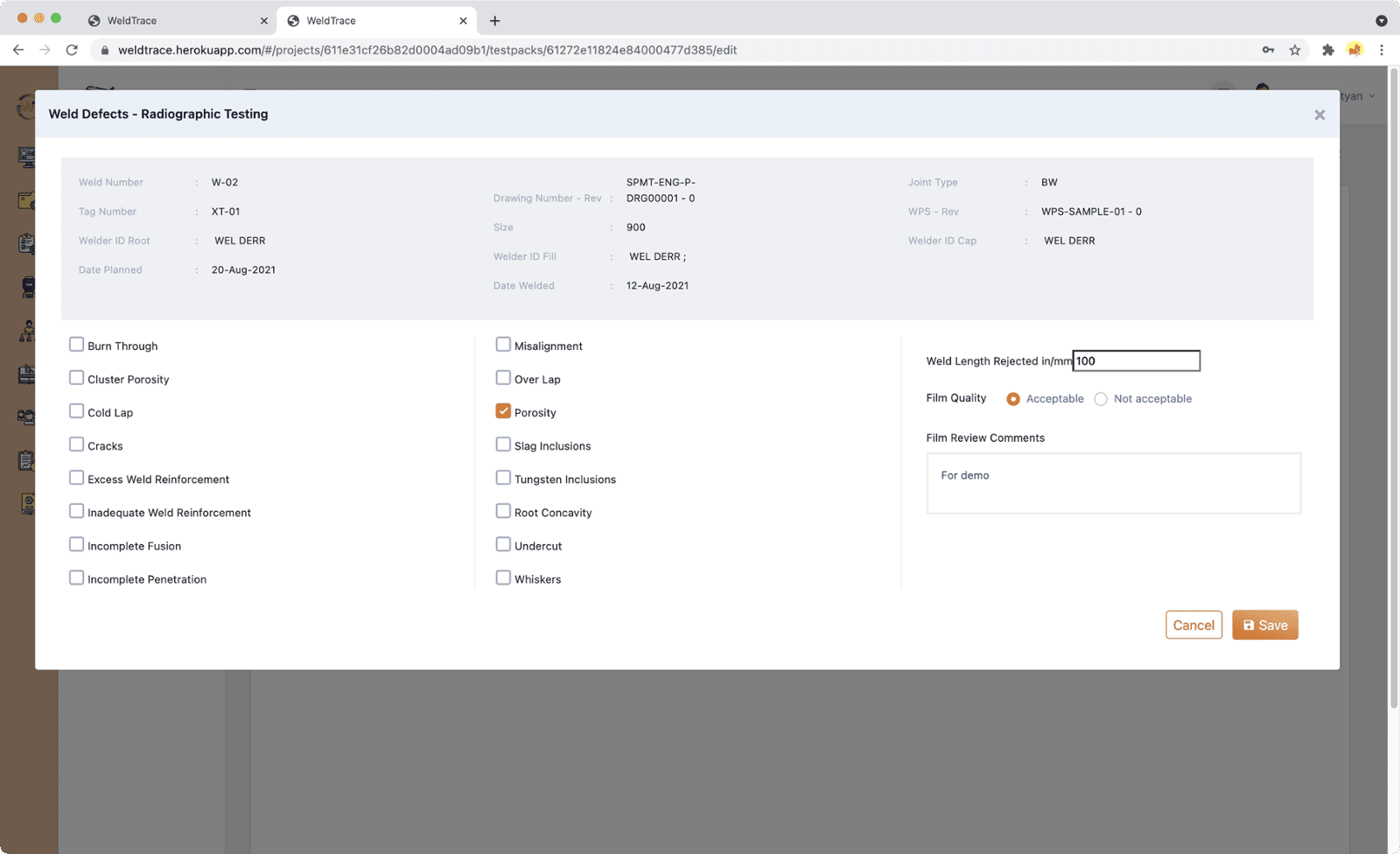

- NDE module to create requests, record results and defects, handle repairs, penalty, tracer and sampling

- Visual inspection for stage-wise inspection of welds

- Work packages to group welds and manage them

- Traveler, control sheet, job card print options

- Generate QR code labels for welds

- Mobile app for welders, supervisors and inspectors

- Instant messaging for communication between project team members

- Welder who is not qualified or out of continuity prevented from being used

- Welder continuity is recorded automatically

Welding project management simplified!

Welding project management simplified!

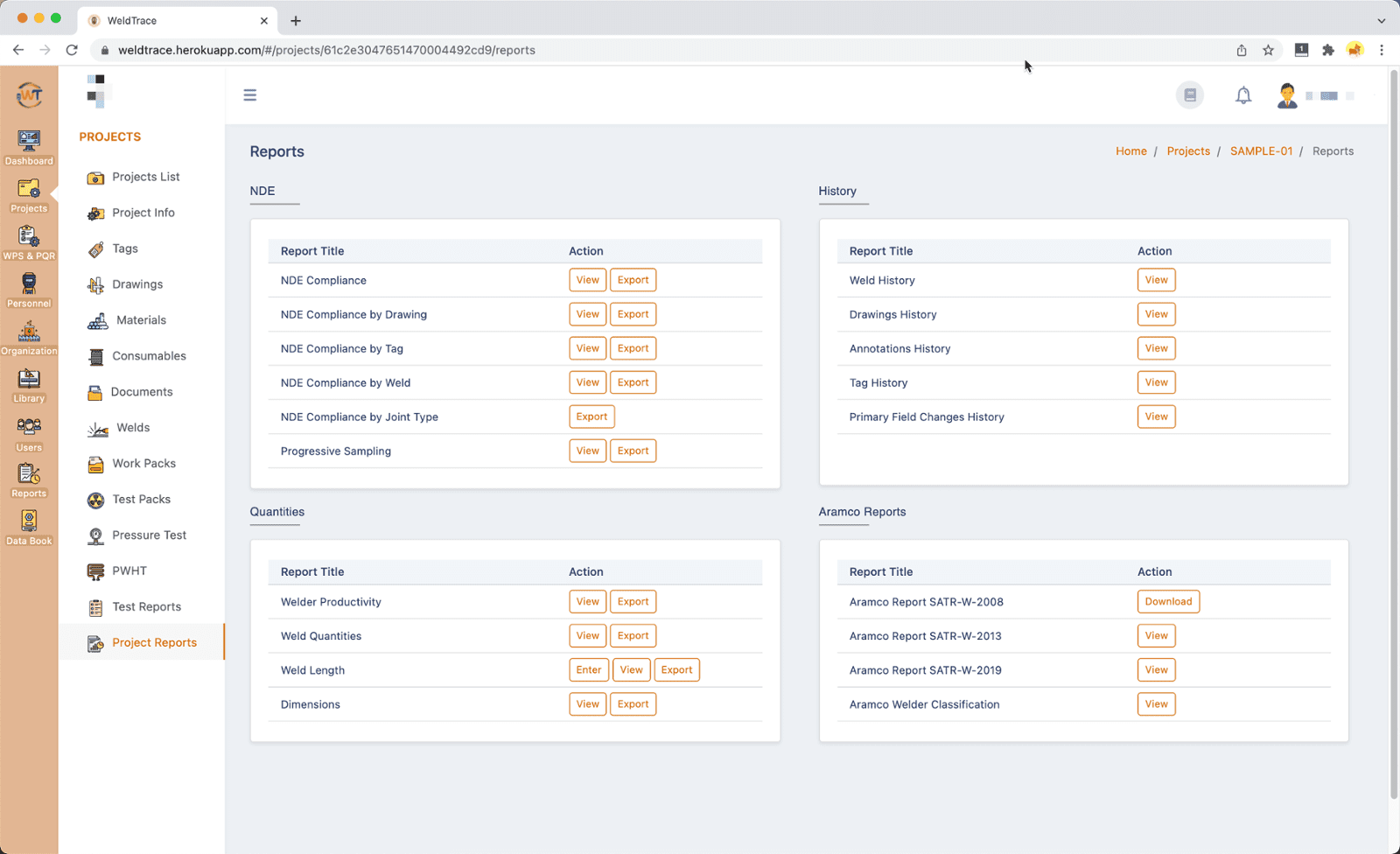

With WeldTrace, managing welding projects or jobs will be so much easier. The project users' roles and access can be defined that will give them access to information and allow or deny them to edit data. History reports will show who has changed what and it is very useful to demonstrate compliance during a client audit.

It is very easy to add data. In addition to forms, WeldTrace has Excel style multiple entry sheets as well as wizards to import data in spreadsheets. Files can be uploaded in bulk and will be matched intelligently with the relevant data.

A separate document control software is not required. Instant messaging will allow users to communicate easily. You can generate welding shop travelers or work packages as PDF files.

Visit this section in our help center to find out more: Managing Projects in WeldTrace

- Role based access to menus and features for users

- Easy to enter data with forms or Excel style spreadsheets

- Import and export data and files with intelligent matching

- Project calendar and Gantt chart for tracking progress

- Welder productivity and performance reports

- Generate PDF files for NDE requests, pressure tests, PWHT

- Create and manage welding work packages

- NDE compliance reports by drawing, tag or weld

- History reports for all changes will help with audits

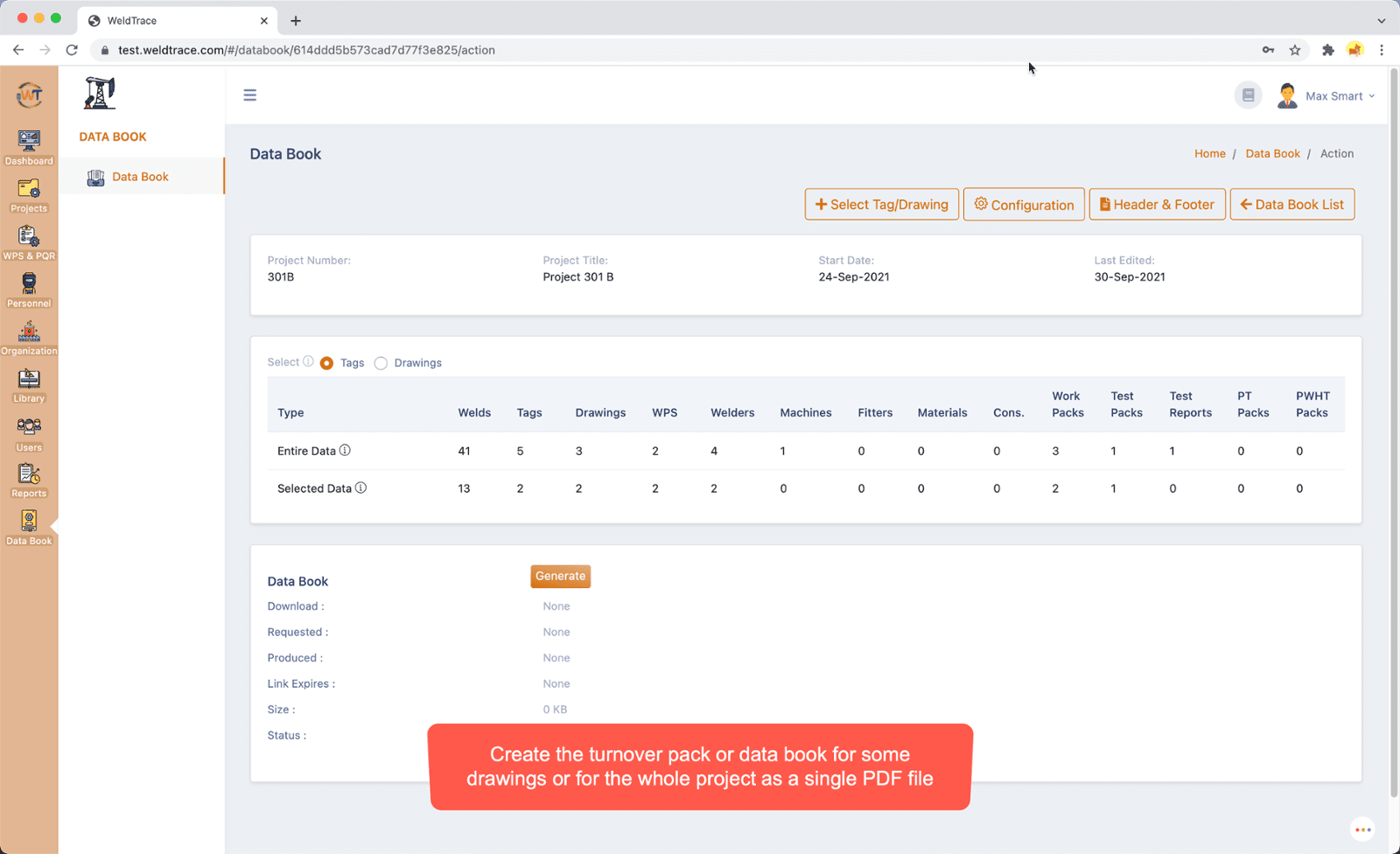

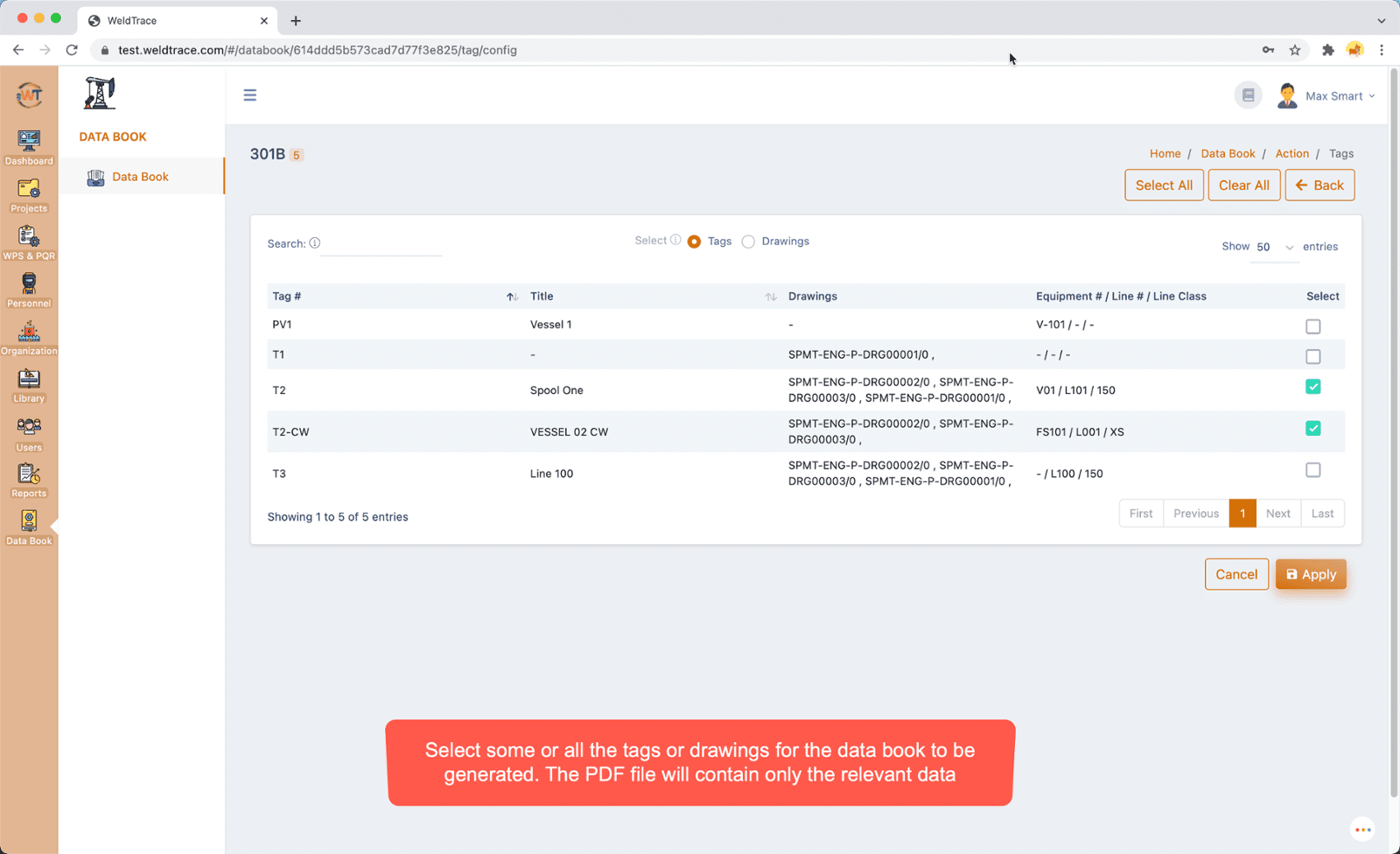

Final project documentation or turnover packs, easy!

Final project documentation or turnover packs, easy!

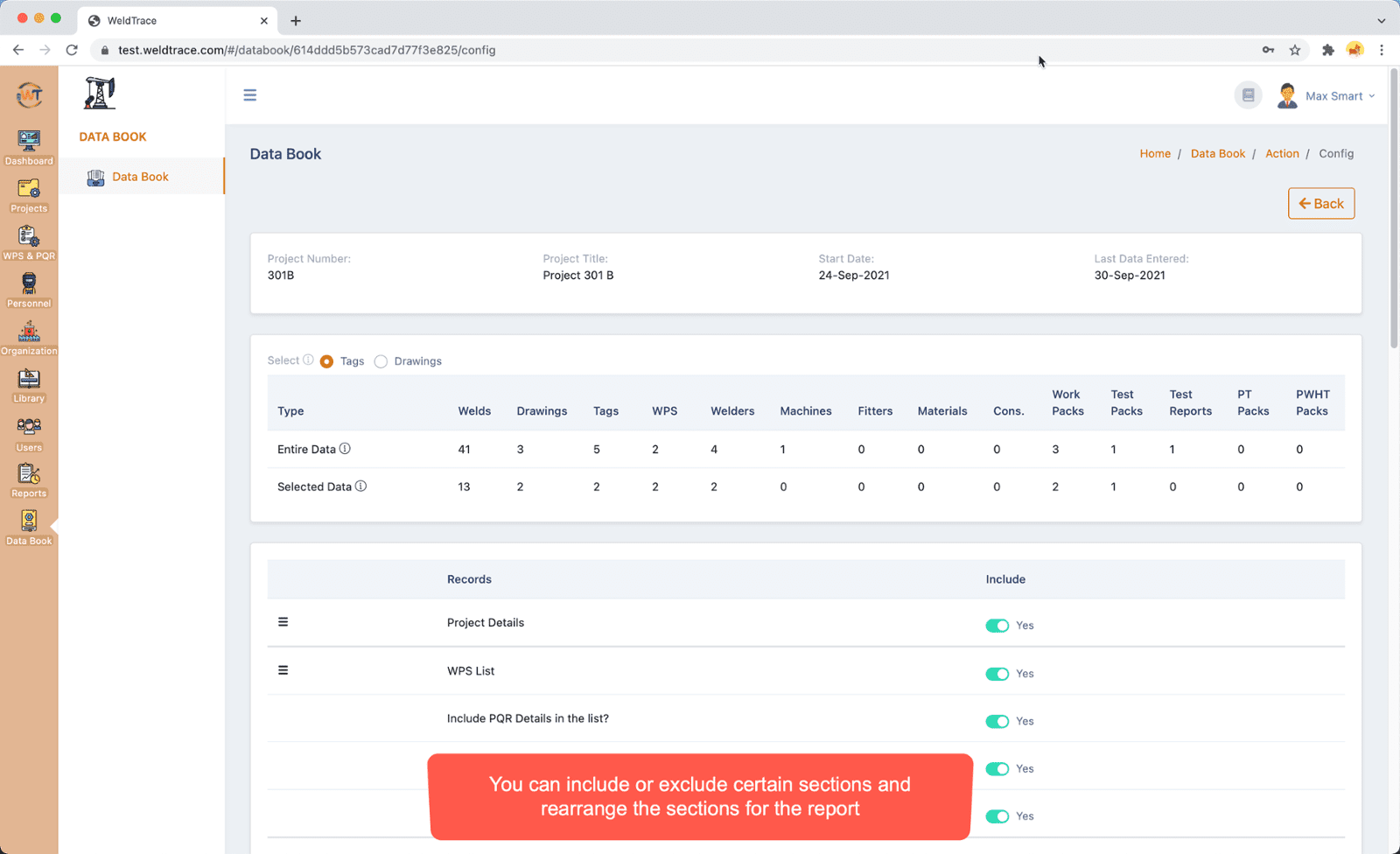

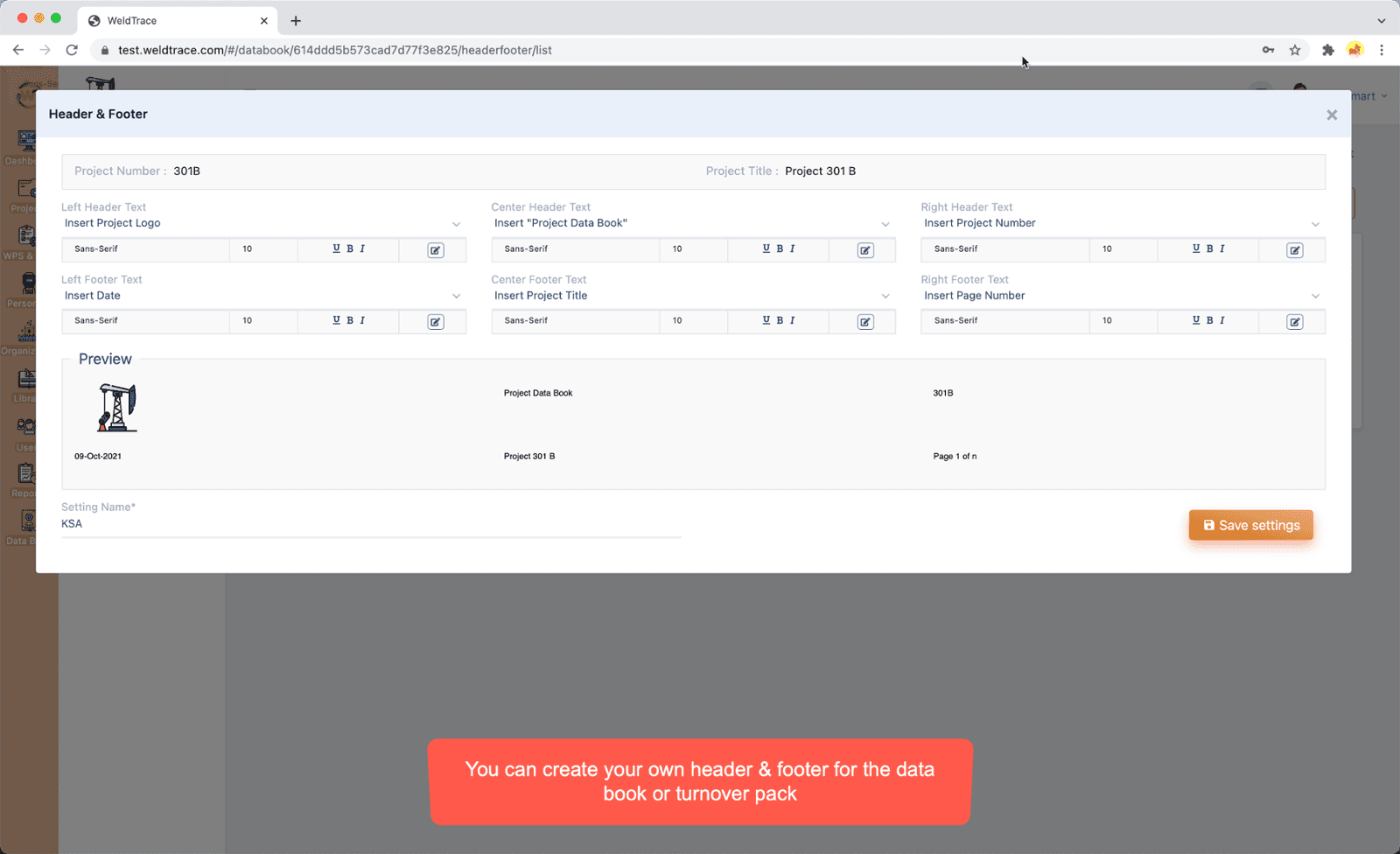

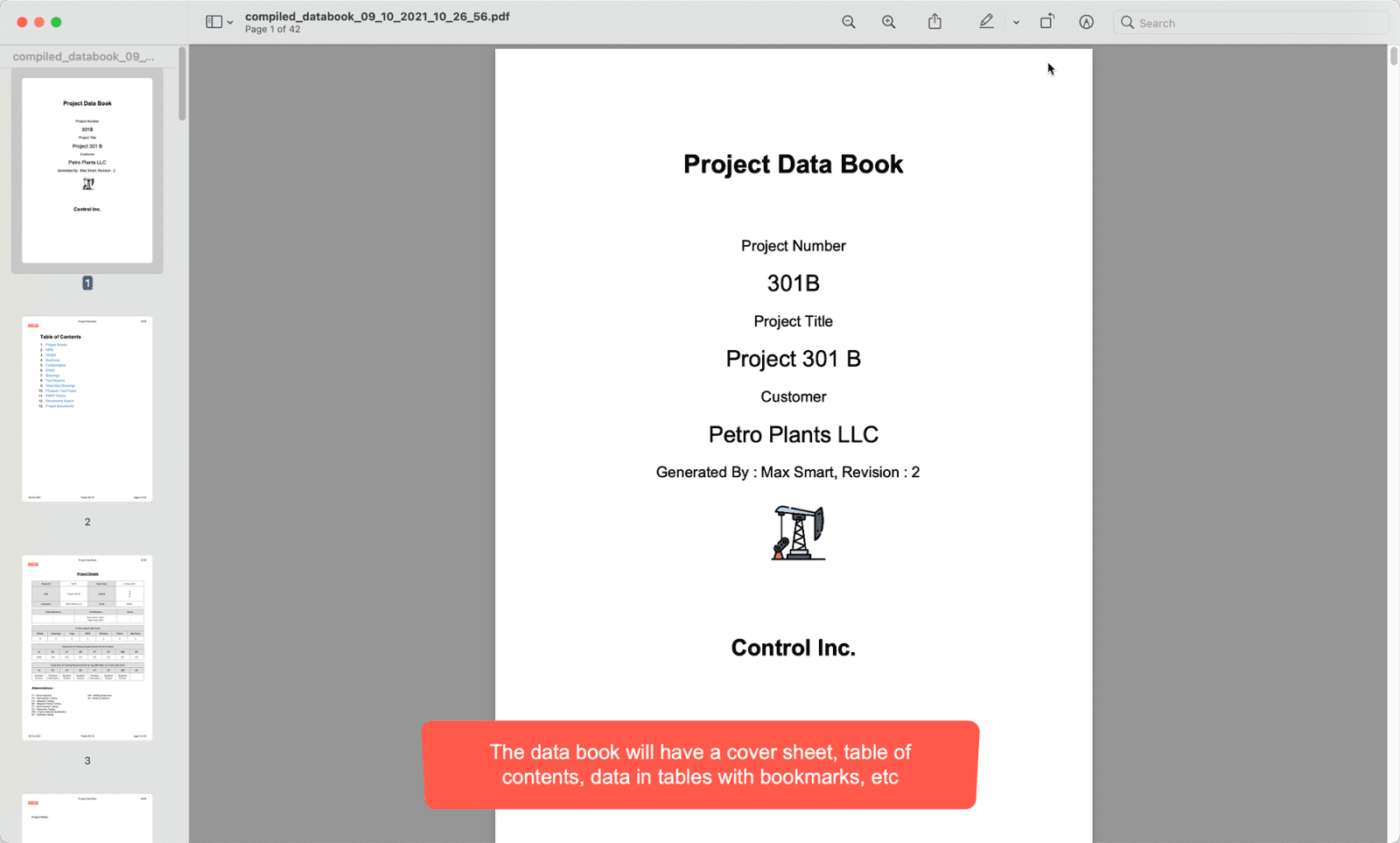

You can generate the project data book, which is also known as the turnover pack or the manufacturer's data report (MDR) for a few drawings or for the whole project with just a few clicks. You can choose what data to be included in which order and even what should appear in the header and footer. WeldTrace will do the magic and create a PDF file that will contain the table of contents, bookmarks, data in tables, file attachments in relevant sections, all neatly stitched in as a single PDF file. Imagine how much time you can save with such a feature. If you missed something or need to generate multiple turnover packs, few more clicks and you get the reports in next to no time.

Visit this page in our help center for more information: Project Data Book

Click here to download a sample data book: Sample Project Welding Data Book

- Produce turnover packs in a few clicks

- Data shown in tables with links to files

- Table of contents and section separators

- Headers and footers can be customized

- Include only what you need to show

- A single PDF file with all the relevant data and records

- Create the data books as and when you need them

- Get through audits confidently

- Will help you navigate the completions and handover process